Many industries create and produce their own products and parts and send them out for sale. As technology improves, the necessary precision of products increases as things need exact measurements. There are many ways to ensure that products are the exact size and shape you need, but one of the best is a Coordinate Measuring Machine (CMM). Here’s what you need to know about CMMs and how they work.

What Is a Coordinate Measuring Machine?

Simply put, a CMM is an advanced tool that uses mechanical and digital methods to measure the dimensions of something. By placing an item on the machine, the CMM can measure its dimensions and check it against the design blueprints to ensure it fits the producer’s requirements.

The Benefits of a CMM

There are many ways to tell if a product or prototype meets the requirements that don’t include a CMM, so why do so many places still decide to use CMM? The initial setup of these devices is complex and takes some investment, but you’ve got the potential to save more than other methods. Additionally, using these machines comes with additional benefits outside of just money which we’ll cover below.

Reduction of Mistakes

A CMM machine has the same benefit as most technology; it lowers the chances of error. People aren’t as accurate as they believe and are likely to make some mistakes when measuring something. Machines are far more precise and can perform the same action repeatedly without making a mistake. So, using these machines helps increase consistency over using people to hand measure.

Accuracy of Measurements

Accuracy is vital when it comes to making a lot of products, where even a few micrometers can make a massive difference in the end product. People struggle to measure small things and may not have the equipment to do so, but these machines can take those measurements. This, along with the reduction of mistakes, are clear benefits to using a CMM as it’ll help create the best measurements consistently.

Faster Measurements

Another reason many people invest in CMMs is their ability to measure an item quickly. Hand measurements and common measuring tactics are slow and require a person to put everything into writing. However, these machines can quickly generate accurate readings that you can rely on whenever you need.

How They Benefit Businesses

While there are many reasons why people trust and use CMMs, businesses need more than that to make a serious investment. So, when it comes to a company using these machines, it all depends on the benefits they’ll see. To get an accurate look at why these tools are so popular, the next section will cover the uses of CMMs for a business.

Speeding Up Production

One of the significant holdups for precision products that need accuracy down to the micrometer is that ensuring proper measurements can take a long time. This slows production and limits how many items a process can make in one day. CMMs can quicken this process and help speed up the production process, especially when you combine it with other machine processes, like CNC plastic machining. This enables you to get more products out daily to increase your production and sell more, potentially increasing profits.

Designing New Products

CMMs are great for prototype turnover rate as you can quickly measure your prototypes to ensure everything is right or send them back if it’s wrong. This helps you create new products quickly and can help you fix anything in your process that’s off before making a bunch of an item. They’re also great for quality control for products that need it, as you can quickly measure something before sending it out to ensure the product functions properly.

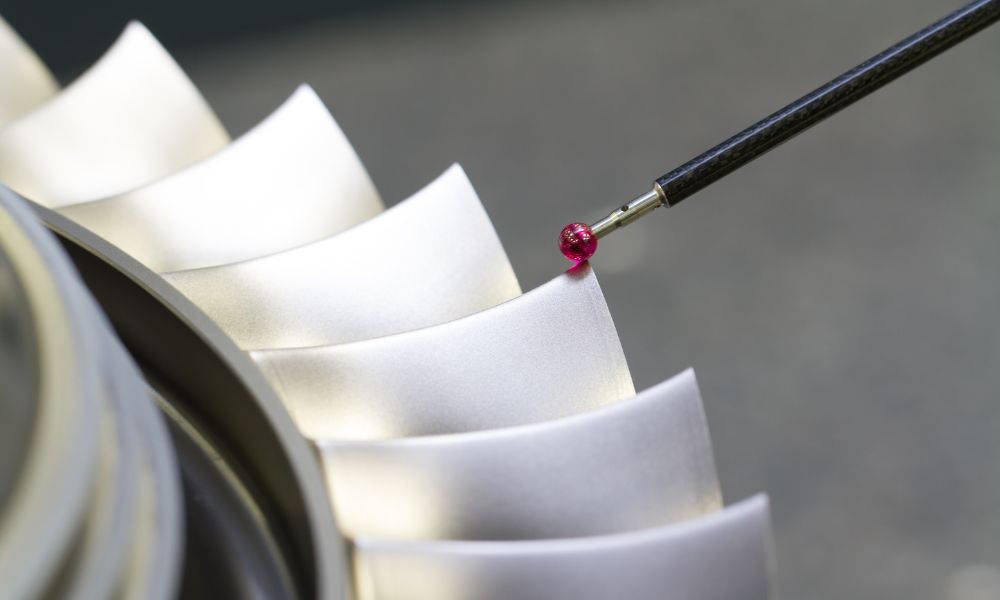

Types of CMMs

While CMMs all function for the same purpose, there are different types of CMMs with various benefits and purposes. You’ll want to find the one best suited for measuring your parts and products to get the most out of your investments. To help you accomplish this, here’s a look at some of the types of CMM out there.

Bridge CMM

This system is one of the most accurate CMMs on the market, which is great for measuring a variety of small- and medium-sized products. It uses sensors to move along the x, y, and z-axis. These sensors create a detailed map of the object to measure it down to the micrometer to ensure everything is as you need it. However, they’re difficult to move and can only measure smaller items while costing a lot of money.

Gantry CMM

Gantry CMMs are very similar to bridge CMMs but are on a much larger scale and can house those larger items that bridge components struggle with. It does feature extra support to make it far easier to load up and scan parts, no matter the size. Just like bridge CMMs, these machines are heavy and expensive, requiring a trained operator to fully use the device. But it’s great for scanning a wide variety of items.

Cantilever CMM

These CMMs are unique as they only use one side to scan something, so they’re only really useful for looking at small items as the sensor can only see so much. These machines are user-friendly as you can access all three sides, making loading and unloading whatever’s in the machine easier. You still have the same issue of needing skilled technicians to run the device.

Optical CMM

Optical CMMs are portable devices you can bring with you to scan an object to get the measurements. These devices are quick but lose some accuracy, making them perfect for all but the most precise designs. They’re far easier to use as you don’t need to program them, and you can measure items of various sizes without restraint with these CMMs.

When it comes to precision in the production of parts and items, you’ll want to know what coordinate measuring machines are and how they operate. They can massively improve your production and help you create the best processes to make your products. Additionally, you can save money using these machines over time, helping you increase your profits and reinvest in your company to grow more and more.

![Read more about the article It’s About Time [And Saving Money]: New Lathe Does turning and Milling Too!](https://www.millerplastics.com/wp-content/uploads/2017/08/equip2-l-300x167.jpg)