Some of the same concepts that govern CNC machining and 3D printing also govern coordinate measuring machines. Luckily, understanding these ideas isn’t as difficult as it may sound; they’re all different avenues people use to create customized parts for clients or projects. CNC machining takes a digital blueprint and simply cuts away at a medium to create a part, while 3D Printing, on the other hand, will use the same blueprint to landscape from the ground up. This article should help you understand what a coordinate measuring machine is and what it does when in operation.

The Probe

The probe is a very sensitively calibrated electronic digit. Its function is to take measurements by creating points of contact and then recording them on solid points of contact when it touches individual parts. It then takes the geometric design of those points and aligns them to send a digital image to the device being used in conjunction with it. These points are all being used for performance standards that must be met to perfect the image specifications.

What Is CMM?

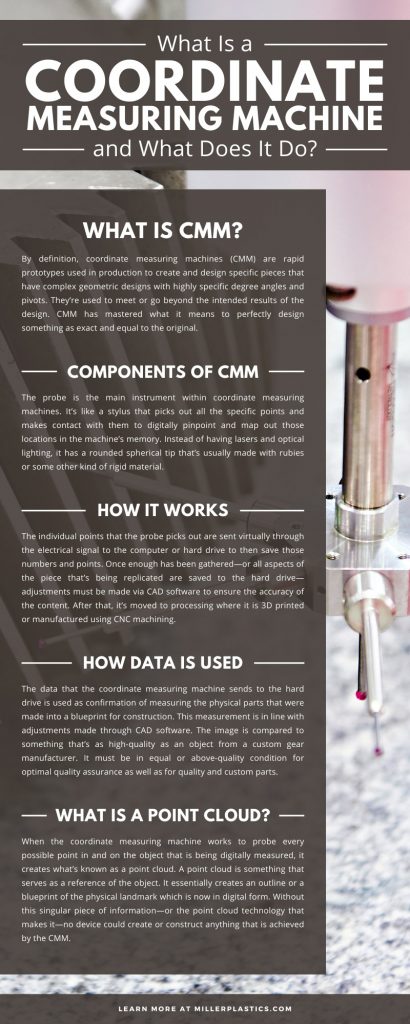

By definition, coordinate measuring machines (CMM) are rapid prototypes used in production to create and design specific pieces that have complex geometric designs with highly specific degree angles and pivots. They’re used to meet or go beyond the intended results of the design. CMM has mastered what it means to perfectly design something as exact and equal to the original.

Components of CMM

The probe is the main instrument within coordinate measuring machines. It’s like a stylus that picks out all the specific points and makes contact with them to digitally pinpoint and map out those locations in the machine’s memory. Instead of having lasers and optical lighting, it has a rounded spherical tip that’s usually made with rubies or some other kind of rigid material. The probes are built with these tips so that they won’t change their structure when the temperature surges. When the probe makes physical contact with another piece, it generates an electrical surge that sends messages to the computer or device.

How it Works

The individual points that the probe picks out are sent virtually through the electrical signal to the computer or hard drive to then save those numbers and points. Once enough has been gathered—or all aspects of the piece that’s being replicated are saved to the hard drive—adjustments must be made via CAD software to ensure the accuracy of the content. After that, it’s moved to processing where it is 3D printed or manufactured using CNC machining.

How Data Is Used

The data that the coordinate measuring machine sends to the hard drive is used as confirmation of measuring the physical parts that were made into a blueprint for construction. This measurement is in line with adjustments made through CAD software. The image is compared to something that’s as high-quality as an object from a custom gear manufacturer. It must be in equal or above-quality condition for optimal quality assurance as well as for quality and custom parts.

What Is a Point Cloud?

As stated earlier in the article, when the coordinate measuring machine works to probe every possible point in and on the object that is being digitally measured, it creates what’s known as a point cloud. A point cloud is something that serves as a reference of the object. It essentially creates an outline or a blueprint of the physical landmark which is now in digital form. Without this singular piece of information—or the point cloud technology that makes it—no device could create or construct anything that is achieved by the CMM.

Programs That Make Use

Certain programs that benefit from this machine generally include machines such as CAD and CNC. These types of machines digitally copy objects to make synthetic variations of them as a means for people to acquire custom machine parts on command. Compared to the tools used by humankind in the past, this technology is a huge step forward. Before, workers used to specifically order pieces by people who focused solely on metallurgy or plastics manufacturing. This was a long and grueling ordeal, and with it, projects would take days or even weeks to get finished. Additionally, there was always the chance that the parts would not come out right or mistakes would be made. Mistakes would, of course, necessitate the order to be redone, which would waste the time and money of everyone involved. Clearly, the technology people can use today is far superior in every single way.

Coordinate Measuring Machines have greatly impacted the way in which specific creative industries make their specialty parts. By making these blueprints, we are not only able to print them as perfectly possible, but we also carry the ability to specialize and edit them to create completely original parts. This technology is more accurate than something like digital scanning due to the angles and crevices inside some of the parts that refract light. When images become distorted, the right angles and points cannot be achieved. So, by pinpointing with the stylus of the probe, an exact point is chosen and saved for every existing angle and point in order to achieve the most exact replica. Replicas could also be achieved if one were to create them by hand, but for obvious reasons—such as being an extremely tedious process—it isn’t highly favored.

Coordinate Measuring Machines are on the rise to becoming the new industry standard for engineering small and large parts alike. Having this kind of equipment in your facility will help with your overall productivity when you’re making custom orders for clients. This article highlights what a coordinating machine is and what it does in the event that you were curious to know how it curates and creates the perfect pieces.