When working on machining projects, engineers, designers, and manufacturers seek materials that meet functional requirements and offer ease of machining. Understanding the best plastics for machining helps optimize production processes, reduce costs, and enhance product performance. In this guide, we will explore some of the top plastics for machining and what makes them stand out.

Delrin (Acetal)

Delrin, or acetal, is a prime choice for precision machining. This plastic boasts excellent dimensional stability that makes it suitable for intricate parts requiring tight tolerances.

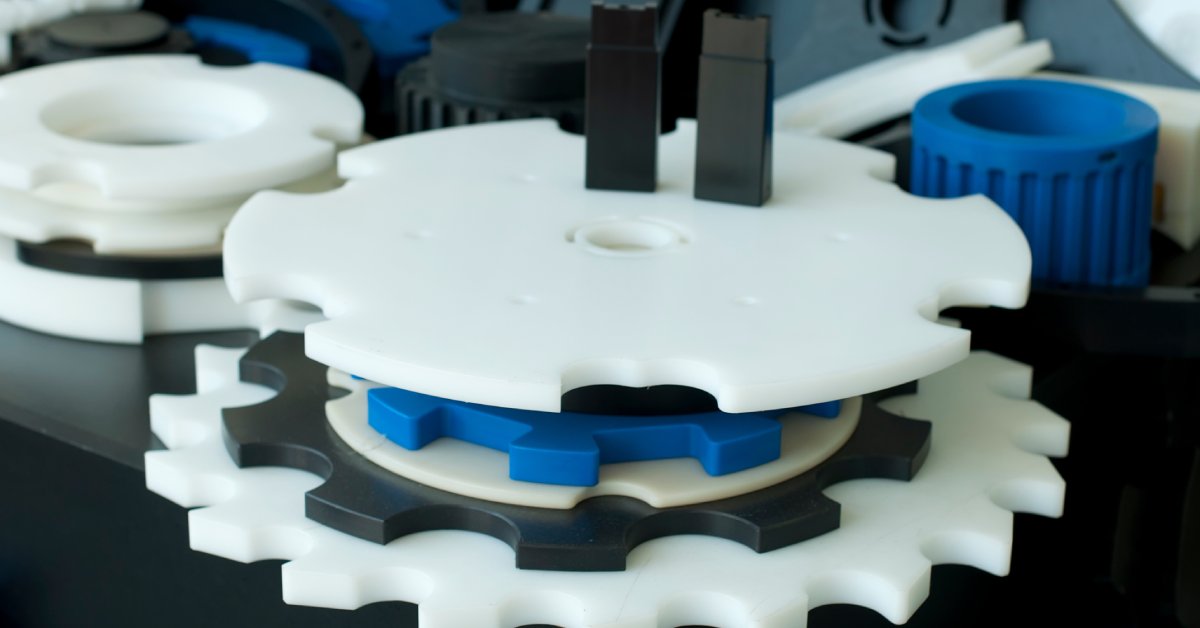

Its low friction coefficient means it doesn’t wear easily, even in applications where parts slide against each other. Plus, its resistance to moisture and chemicals keeps it durable in various environments. These properties make Delrin an ideal material for gears, bearings, and bushings.

Nylon

Nylon stands out for its toughness and resilience. It provides an excellent balance between strength and elasticity. It handles well in machining, which makes it versatile for diverse applications.

Its ability to withstand high temperatures and resist wear and tear makes it invaluable in many applications, including the automotive and aerospace industries. Additionally, nylon’s impact resistance and vibration-dampening qualities make it perfect for components that endure mechanical stress.

PTFE (Teflon)

PTFE is commonly known as Teflon, and it shines in applications requiring extreme temperature resistance and chemical inertness. Machinists appreciate PTFE for its smooth surface finish and nonstick properties, which help keep components moving freely. Furthermore, its dielectric properties make it suitable for electrical insulators and seals.

PVC

PVC (polyvinyl chloride) offers excellent machinability and cost-effectiveness for numerous applications. Its robustness makes it a favorite in industries like construction and plumbing. PVC stands up well against water and chemical exposure, which makes it ideal for pipes, fittings, and valves.

Its ease of machining allows for the creation of complex shapes and structures without compromising strength. You can consult Miller Plastic Products for expert insight on plastic machining and custom solutions to adapt PVC to diverse project specifications.

Polycarbonate

Famed for its high impact resistance, polycarbonate is a go-to material for products requiring clarity and toughness. It machines smoothly, which helps to provide precise detailing without cracking or shattering. Its optical clarity rivals glass, yet it remains lightweight and shatterproof. This makes polycarbonate an excellent choice for protective barriers, lenses, and transparent enclosures.

Using the best plastics for machining is important for achieving the results you want in production processes. If you need help, turn to Miller Plastic Products. We’re ready to provide expert guidance and bespoke machining solutions to make sure that your projects benefit from the highest-quality materials and artisanship.