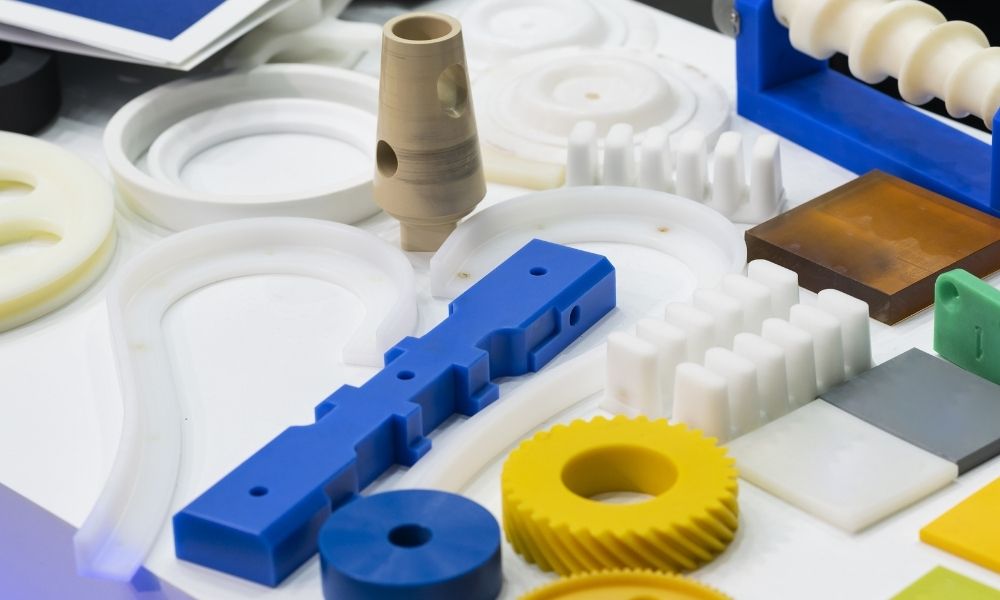

Designing a part is a balancing act. You’re envisioning something that needs to be technically accurate, high functioning, cost-effective, efficient, and fast to produce. A little strategy goes a long way, though, so try these tips for machined plastic component design. They’ll save you time and money, but more importantly, they’ll save you a lot of frustration.

Choose the Best Material

With so many innovations, you might not be up on all your polymers. At Miller Plastics, we help narrow down your options and have the experience to point you in the right direction. Each plastic has different characteristics, creating endless variables. If you design with the right material in mind, things will go more smoothly. Some considerations:

- Temperature: What thermal stress occurs during normal use? During extreme use? How does the temperature affect assembly, finishing, and shipping?

- Chemical Resistance: Plastics all have strengths and weaknesses, and a chemical resistance chart is the best way to determine how your part will react to solids, liquids, and gases.

- Regulations: Keep an eye toward the governmental and private standards for heat resistance, flammability, and electrical and mechanical capabilities.

- Assembly: The material needs to be optimal for all steps of assembly, like bonding and welding.

- Finish: The resin should have the right finish, too, whether that’s glossy, smooth, or a certain color.

- Cost: Raw material price is just the start. Add in the costs of manufacturing, maintenance, assembly, tooling, and finishing.

- Availability: Is the material locally accessible in the right amounts?

Consider Different Processes

Your first instincts might not be the best ones for your project. A few options:

- 3-D Printing: Additive processing is evolving every day and is great for complicated design. It’s still limited in terms of material, but that’s changing, too. Bear in mind that post-processing is often needed to achieve cosmetic standards and tight tolerances.

- Injection Molding: This method is falling out of favor due to the high start-up costs and long lead times. Complex geometries usually require breaking the design down into more parts.

- CNC Machining: Most projects are turning to CNC machining for design flexibility, complicated projects, tight tolerances, and superior surface finishes. It’s efficient, too, since the software can be reprogrammed quickly. You can count on CNC to capitalize on the latest materials.

The Little Things

Production time, cost, and quality can all be improved with these key tips for machined plastic component design:

- Ensure that wall thickness is uniform and at least 1.5 mm.

- Stick to standard-sized holes.

- Avoid deep cavities.

- Round internal corners.

- Eliminate the smallest features.

Consulting with your manufacturer early can prevent complications later. Miller Plastics can advise you on best practices for custom machined plastic parts. Contact us for more information, or visit our facilities in Burgettstown, PA.