Just like many of the products that we use daily, PVC has a similar story in that it should not have existed, and yet we use it in so many applications. Just about any major industry, you can think of uses for it due to its multi-functional properties that give it a spectrum of purposes. The history and development of PVC piping have been pivotal in our development in society, as it has done so much to help the advancement of our civilization.

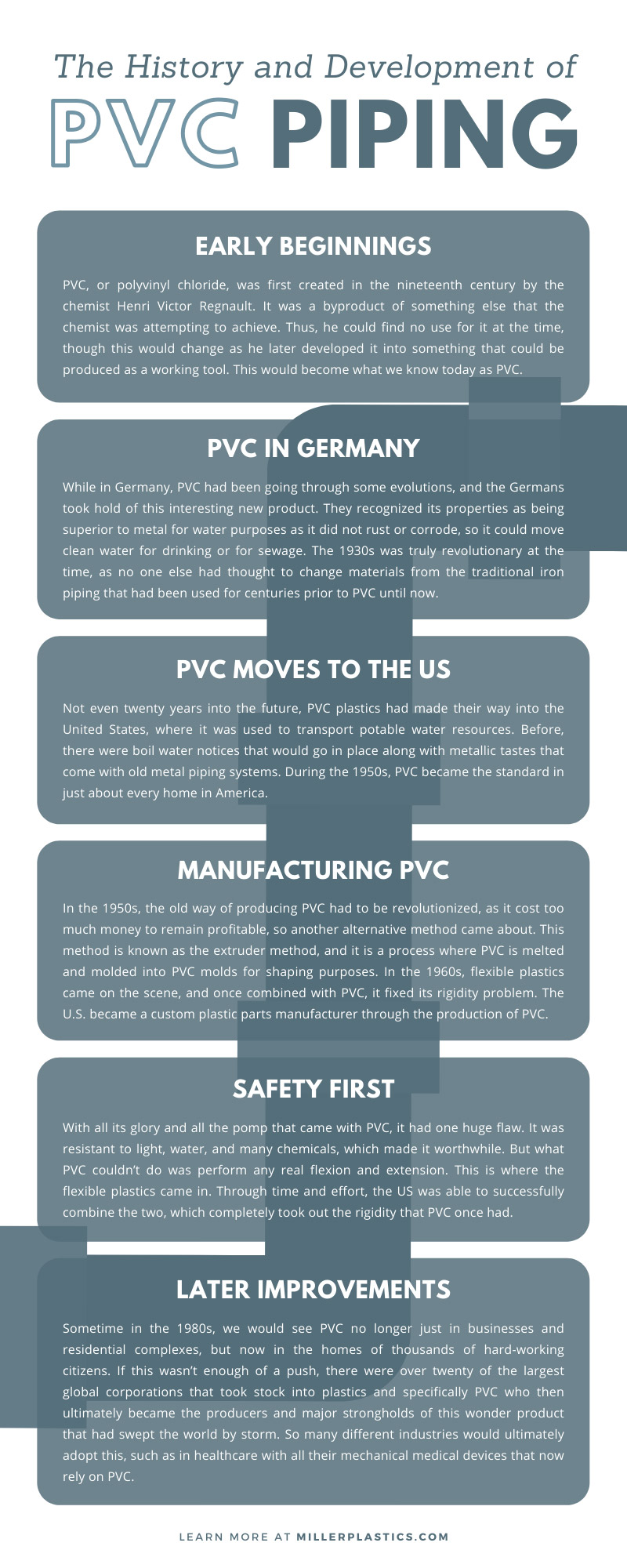

Early Beginnings

PVC, or polyvinyl chloride, was first created in the nineteenth century by the chemist Henri Victor Regnault. It was a byproduct of something else that the chemist was attempting to achieve. Thus, he could find no use for it at the time, though this would change as he later developed it into something that could be produced as a working tool. This would become what we know today as PVC. Now it is malleable and can be shaped for just about any job or tool like pipes and gears.

PVC in Germany

While in Germany, PVC had been going through some evolutions, and the Germans took hold of this interesting new product. They recognized its properties as being superior to metal for water purposes as it did not rust or corrode, so it could move clean water for drinking or for sewage. The 1930s was truly revolutionary at the time, as no one else had thought to change materials from the traditional iron piping that had been used for centuries prior to PVC until now.

PVC Moves To the US

Not even twenty years into the future, PVC plastics had made their way into the United States, where it was used to transport potable water resources. Before, there were boil water notices that would go in place along with metallic tastes that come with old metal piping systems. During the 1950s, PVC became the standard in just about every home in America. This changed how we view our water quality and how we resource our water, due to PVC’s properties of providing pure, clean water that does not need as much testing. As the older counterpart, when used with metal piping, potable water would produce something clean but not always desirable.

Manufacturing PVC

In the 1950s, the old way of producing PVC had to be revolutionized, as it cost too much money to remain profitable, so another alternative method came about. This method is known as the extruder method, and it is a process where PVC is melted and molded into PVC molds for shaping purposes. In the 1960s, flexible plastics came on the scene, and once combined with PVC, it fixed its rigidity problem. Most of the issue was that it was taking too much energy to roll out the heated powder to produce the product on a consistent basis. By heating the mold, the metal of the mold could hold the heat for longer periods of time instead of having a consistent heat burning. This would cost a lot less to manufacture than the original way of production and ultimately make it cheaper and more profitable. Therefore, the U.S. became a custom plastic parts manufacturer through the production of PVC.

Safety First

With all its glory and all the pomp that came with PVC, it had one huge flaw. It was resistant to light, water, and many chemicals, which made it worthwhile. But what PVC couldn’t do was perform any real flexion and extension. This is where the flexible plastics came in. Through time and effort, the US was able to successfully combine the two, which completely took out the rigidity that PVC once had. Otherwise, the original forms were subject to water bursting the pipes under extreme pressure situations, or even something as small as installation could cause it to break without the implementation of the new flexible plastic into the PVC. Flexible plastics would now become the future of plastic innovation, but also made way for PVC to reach its full potential in what it has become today—a major resource for plumbing, among many other utilities.

Later Improvements

Sometime in the 1980s, we would see PVC no longer just in businesses and residential complexes, but now in the homes of thousands of hard-working citizens. If this wasn’t enough of a push, there were over twenty of the largest global corporations that took stock into plastics and specifically PVC who then ultimately became the producers and major strongholds of this wonder product that had swept the world by storm. So many different industries would ultimately adopt this, such as in healthcare with all their mechanical medical devices that now rely on PVC. IT would begin to use it for applications such as piping Ethernet cables and fiberoptics underground and in crawlspaces: textiles, and construction for things such as pouring elements like concrete. And of course, we can’t leave out construction, as it works to fuel both our plumbing and even some HVAC accessories that help us with heating and air cooling.

There are so many ways that plastics have helped to mold and shape the world that we live in today due to the commonplace that they have taken among us. They have taken over many of the jobs that would eventually need repair and replacement, such as metalwork and wooden structures. No other substance to date has been able to stand the test of time quite as well as polymers have, specifically speaking to PVC. So, we have a lot to be thankful for, even with such sudden achievements.

This has been the history and development of PVC piping throughout the 19th century and until the present day. Never has there been a time when we have had a material so versatile and workable as PVC, and the unique benefits it has provided for society. And these aren’t the limitations of what PVC is capable of, so there may be more to look forward to with this product as time goes, and as we develop new utilities for using PVC.