Most plastics exhibit different degrees of quality and usefulness that they all exhibit. The manufacturing process has the ability to give these plastics their strength and durability. The differences between them are seen as resourcefulness, as they all have qualities that suit certain specific jobs. Therefore, there is no waste in the manufacturing process of plastics. Here are some of the differences between thermoplastics and thermoset plastics.

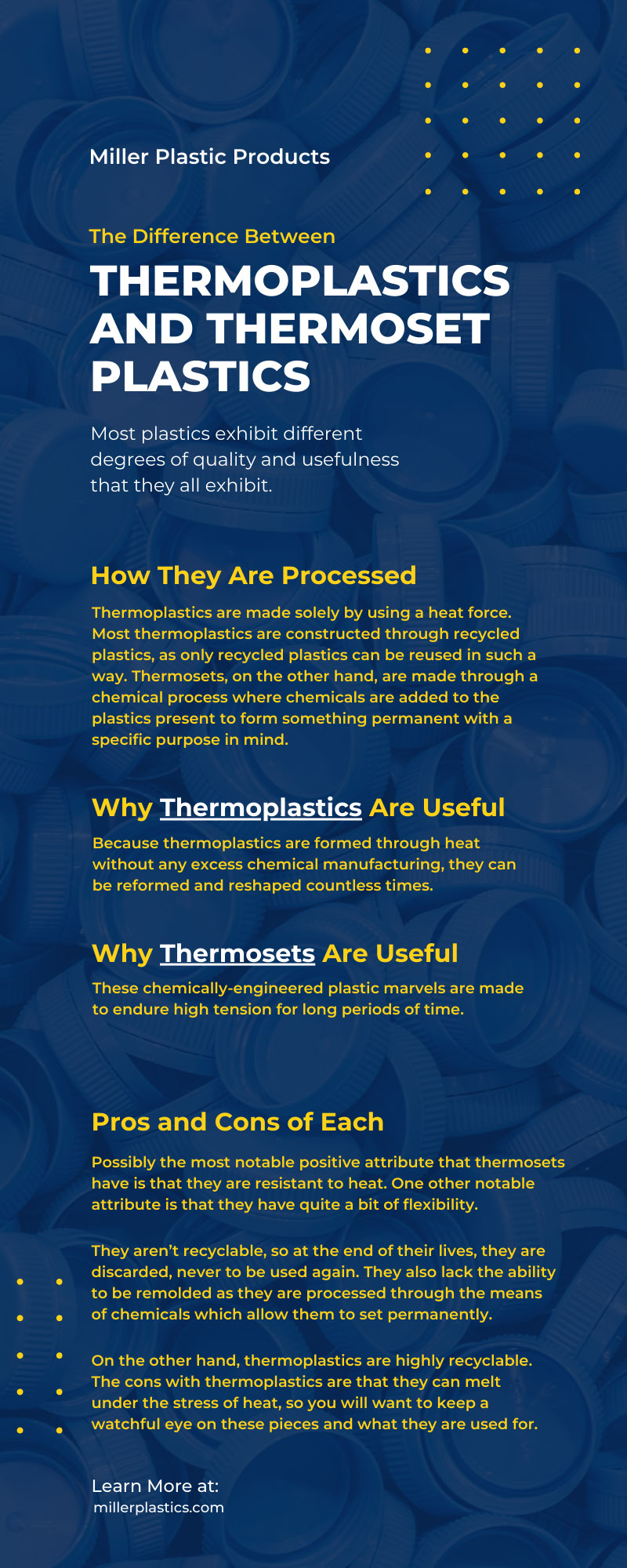

How They Are Processed

First, we must take into consideration the ways in which both types of plastics are manufactured. Then, we can discuss why they are manufactured that way and what we determine to be useful. The attributes from both that we use and utilize in our industrial pursuit make plastic parts and machining through plastic parts fabrication. Thermoplastics are made solely by using a heat force. Most thermoplastics are constructed through recycled plastics, as only recycled plastics can be reused in such a way. Thermosets, on the other hand, are made through a chemical process where chemicals are added to the plastics present to form something permanent with a specific purpose in mind.

Why Thermoplastics Are Useful

Because thermoplastics are formed through heat without any excess chemical manufacturing, they can be reformed and reshaped countless times. This is extremely important because they can be continuously recycled whenever they wear down or no longer have usefulness in the specific job. They can also be reshaped and fitted to their original size and shape to be used multiple times. So, they have longevity in their ability to be molded through heat.

Why Thermosets Are Useful

When you think of thermosets, you should think more along the lines of the industrial gears and mechanical pieces that are constantly under pressure and force. These chemically-engineered plastic marvels are made to endure high tension for long periods of time. Having these tools readily available at only a fraction of the cost to produce makes for an excellent alternative when looking for something durable and strong that will last equally as long or longer than its counterparts, such as metals and other elements.

Pros and Cons of Each

Possibly the most notable positive attribute that thermosets have is that they are resistant to heat. This is an incredible feat, as many machines are consistently under high tension and working in pressure-filled situations, which produces high levels of heat. This feature is important for these plastics, as they can tolerate and work well in these conditions for long periods of time without fail. One other notable attribute is that they have quite a bit of flexibility. Only high-pressured machines can achieve these flexibilities under tension when it comes to thermosets. This is important because their strength makes them competitive with metals.

The undesirable qualities that come with thermosets aren’t many, but they do exist. They aren’t recyclable, so at the end of their lives, they are discarded, never to be used again. They also lack the ability to be remolded as they are processed through the means of chemicals which allow them to set permanently. This limits what they can and cannot do, but it is not the end of their resourcefulness, as we will learn that they are renewable.

On the other hand, thermoplastics are highly recyclable. Not only can they be recycled and reshaped, but they are also impact-resistant. Believe it or not, thermoplastics are also resistant to other chemicals. They have a high level of finishing options in case you decide that you need a specific type to go with whatever you are using them for in your office or business. The cons with thermoplastics are that they can melt under the stress of heat, so you will want to keep a watchful eye on these pieces and what they are used for.

So, there are two conditions that you will need to wager—whether to go with the thermoplastics that can be recycled, reused, reshaped, or used for other innumerable applications solely with heat. As the cheaper alternative, thermosets have a long life and are less costly to produce due to their chemical nature. However, if thermoplastics can be recycled and used for virtually anything, then it begs the question of which is most cost-effective. You will ultimately have to make this decision based on your specific needs.

Curing of Thermoplastics

Recyclable plastics are collected and then used by softening until melted into a fluid, and then all these plastics are then bonded while in liquid form to reform into thermoplastics. Once formed, these plastics will now be resistant to shrinking, cracking, and can be rebuilt with heat—and no chemical processes are necessary to achieve this. They also have a certain level of aesthetic that comes with them, as they can be shaped and molded as finely as you can imagine. They are also anti-slip, so they have a nice grip and toughness about them. They do not corrode, and most importantly, they are electrically insulated. So, they can also insulate against electricity, making them safer than just regular plastics that may or may not insulate raw electricity.

Curing of Thermosets

Thermosets operate a little bit differently due to how they are processed. Thermosets are produced using what is known as reaction injection molding. It is also known as a resin transfer molding process. What happens is that these thermoset plastics for polymers create permanent chemical bonds that create monomer chains in the process. Once these monomers become present, then the process is complete, and they are permanently formed. The takeaway from thermosets is that they have the greatest strength and endurance of the two types, with a very high-end load that they can withstand. This means that they don’t break, reshape, or tamper under a lot of stress and impact.

Both thermosets and thermoplastics have their place, and both serve different aspects of the industrial economy. With recycling on the mend, thermoplastics are gaining a lot of traction as they are being used and reused constantly, and these plastics are being mass-produced with materials already available to anyone. On the other hand, thermosets are also being put into mass production, as their long-life expectancy provides hard-working tools needed for industrial use that will not quit any time soon. There are plenty of differences between thermoplastics and thermoset plastics, but they work toward the same goal, which is to provide assistance in any possible scope.