Modern plastics have revolutionized almost every industry; in fact, they’re impacting our day-to-day lives in ways we may never realize. Each innovation builds on the ones that came before, and we’ve grown accustomed to the parade of miracle materials: rayon, nylon, acrylic, Kevlar, Teflon, and more. With the invention of acetal in the ’50s, the Age of Plastics gave manufacturing one of its greatest gifts.

There are many advantages of using acetal plastic for fabrication, but engineers often sum it up this way: Acetal is the most machinable plastic. It’s ideal for precision parts because it has such high strength and low friction, as well as excellent dimensional stability and low moisture absorption. That all adds up to great machinability.

At Miller Plastics, we often turn to acetal when a precision part needs to be strong, slippery, or flexible—or all three. Acetal is unique in that it is inherently slippery, so it’s ideal for reducing friction. It’s a material that’s well suited for sliding mechanisms, gears, or even the plastic molded protectors you find at the bottom of furniture legs. That’s right: Thanks to acetal, you can slide your sectional across a wood floor.

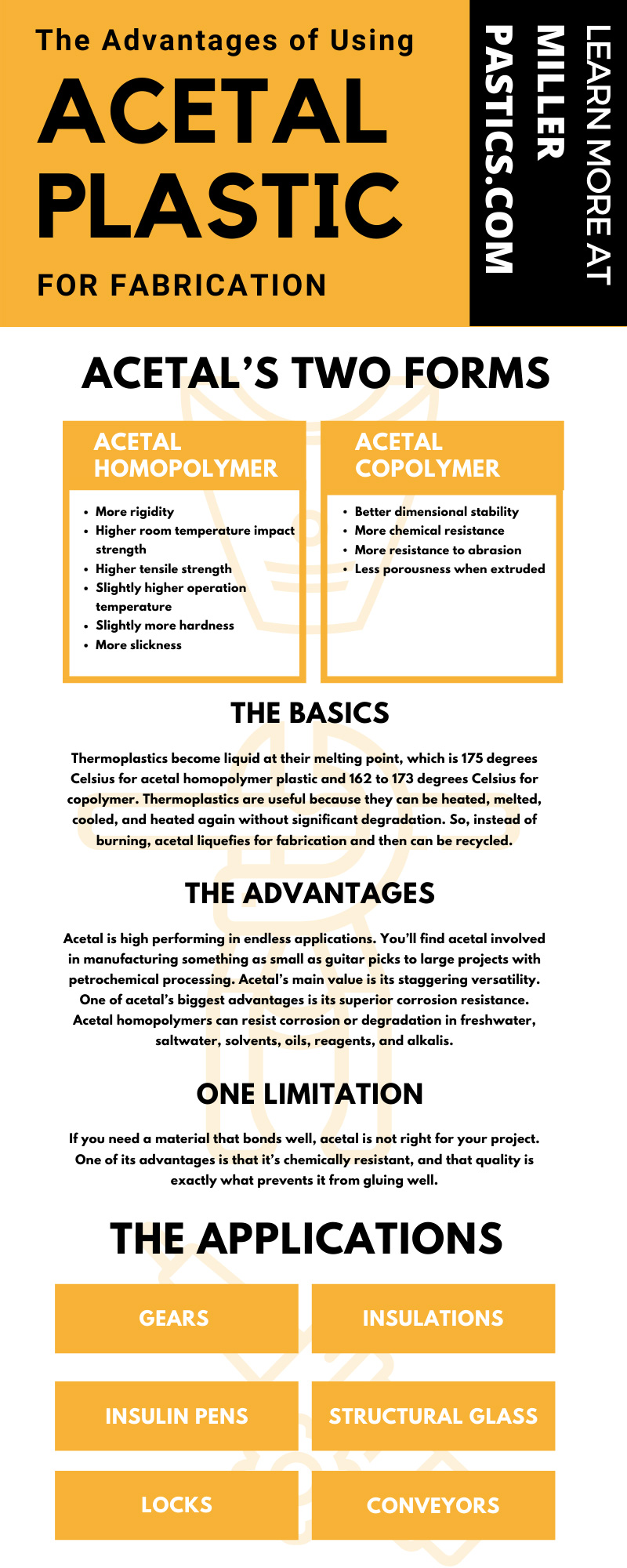

Acetal’s Two Forms

Acetal thermoplastic is also known as Polyoxymethylene, or POM. It’s a resin that occurs in a white semi-crystalline state. Acetal has two categories, and each has some distinctions:

Acetal Homopolymer

Homopolymers consist of repetitive monomer units with a similar molecular structure exhibited by each unit. In comparison to copolymers, homopolymers have:

- More rigidity

- Higher room temperature impact strength

- Higher tensile strength

- Slightly higher operation temperature

- Slightly more hardness

- More slickness

Acetal Copolymer

Copolymers are made out of different types of monomer units, which combine to form a common polymer structure. In comparison to homopolymers, copolymers have:

- Better dimensional stability

- More chemical resistance

- More resistance to abrasion

- Less porousness when extruded

The Basics

Acetal is called a thermoplastic because of the way it responds to heat. Thermoplastics become liquid at their melting point, which is 175 degrees Celsius for acetal homopolymer plastic and 162 to 173 degrees Celsius for copolymer. Thermoplastics are useful because they can be heated, melted, cooled, and heated again without significant degradation. So, instead of burning, acetal liquefies for fabrication and then can be recycled.

Acetal is sold under brand names such as Celcon, Duracon, Kepital-POM, Tecaform, Tepcon, Hostaform, and Ultraform. You may also have heard of acetal by the name of Delrin. That’s the name trademarked by DuPont for an acetal homopolymer that’s in common use. In the United States, Delrin is usually sold in rods or sheets.

Acetal is available on the market in its granulated form. Manufacturers apply heat and pressure until it’s liquid and can be molded into different shapes. Acetal was originally intended to compete with zinc and aluminum castings and is a favorite go-to material for projects that need the best properties of plastic without the full strength of metal.

The Advantages

Acetal is high performing in endless applications. You’ll find acetal involved in manufacturing something as small as guitar picks to large projects with petrochemical processing. Acetal’s main value is its staggering versatility.

One of acetal’s biggest advantages is its superior corrosion resistance. Acetal homopolymers can resist corrosion or degradation in freshwater, saltwater, solvents, oils, reagents, and alkalis. Mineral acid solutions are the only exception for acetal; over time, hydrochloric, nitric, and sulfuric acids can eat away at the material. Here’s an overview of the other characteristics that make acetal so versatile:

- High tensile strength

- Natural rigidity

- Excellent dimensional stability

- Low water absorption

- Low friction

- Low thermal expansion

- Excellent creep resistance (“creep” is the tendency for a material to stay bent if left under stress for too long)

- Excellent abrasion resistance

- Low centerline porosity

- Continuous operating temperature of up to 185 degrees Celsius

- High lubricity (acetal is often mistakenly believed to be self-lubricating)

- Laser cuts well

- Excellent wear in both wet and dry environments

- Compliance with FDA, USDA, NSF, Canada AG, and 3A-Dairy

- Available in natural and black, but it can be dyed

One Limitation

If you need a material that bonds well, acetal is not right for your project. One of its advantages is that it’s chemically resistant, and that quality is exactly what prevents it from gluing well.

The Applications

Acetal is one of the most widely used plastics in manufacturing, with applications in these industries and more.

Mechanical: gears, pulleys, rollers, bearings, bushing, cams, valves, seals, gear wheels, fasteners, lock systems,

housing parts, chains, nuts

Electronics: insulations, connectors, parts of various consumer electronic devices

Automotive: vehicle fuel sender units, power windows, door locks, turn signals, vehicle tanks

Sports: landing skids, yo-yos, paintball accessories, airsoft guns

Medical: insulin pens, metered-dose inhalers

Food: milk pumps, conveyors

Hardware: locks, handles

Musical: picks, bagpipes, instrument mouthpieces, flutes, drum stick tips

Construction: structural glass

Kitchenware: coffee brewers, knife handles

Comparison To Nylon

Acetal and nylon are both semi-crystalline thermoplastics, and have similar characteristics such as chemical resistance, fatigue resistance, and wear resistance with a sharp melting point. They are both often used for small components such as washers and spacers. However, acetal and nylon are not interchangeable.

For starters, they look different. Acetal is shiny, while nylon is duller. They perform differently, too.

Nylon has more superior tensile strength and bending stiffness than acetal, and it can handle higher loads and temperatures. Nylon, though, can be susceptible to damage from UV radiation and changes in humidity. Compared to nylon, acetal provides higher impact and cold resistance, making it well suited for moderate loads.

The advantages of using acetal plastic for fabrication are obvious: It’s easy to machine and tough to wear out. Miller Plastics has been in manufacturing for five decades, and we’ve witnessed the wonders of acetal countless times. Our experience and extensive plastic fabrication services can help you decide on the best materials and methods for your project. For the highest-quality custom pieces at the lowest prices, contact us for a quote, or visit our state-of-the-art facilities in Burgettstown, Penn., near Pittsburgh. We look forward to working with you.