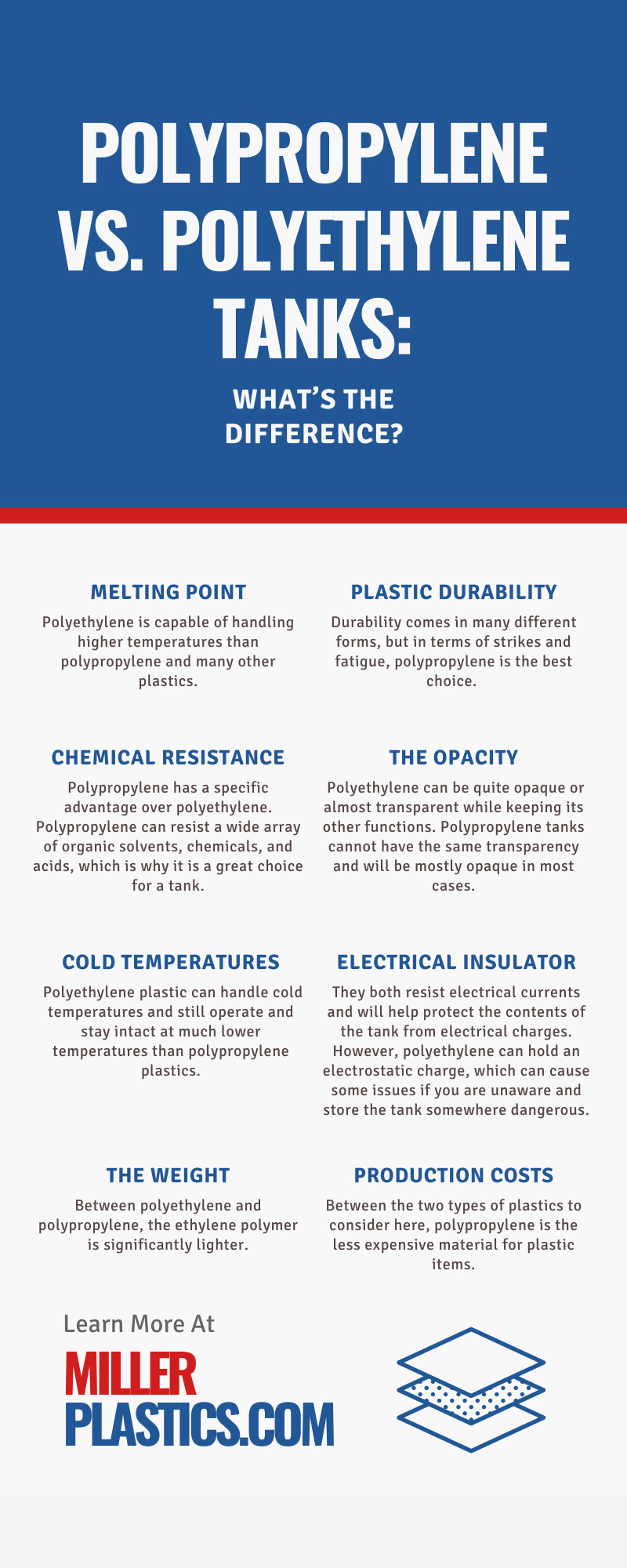

While many people think of plastic as one type of material, there are many different types of plastic. It is important to understand their uses if you need a product that uses plastic because you will get very different results depending on your choice. One common choice people need to make is what kind of plastic tank to purchase to hold liquids. While there are many kinds of plastic tanks, polypropylene and polyethylene are the two common options. So, what is the difference?

Chemical Difference

The first thing you should know about the types of plastics is how they differ from each other on a chemical level. Many plastics have a very similar chemical makeup, but slight changes to the chemicals lead to massive variations in the final plastic product. Polypropylene and polyethylene have mostly the same chemical makeup but use different monomer units in their processing. Polyethylene uses ethylene monomer units, and polypropylene uses propylene monomer units. This ends up creating plastics with very distinguishable features.

Practical Differences

While the chemical differences between plastics are important parts of creating plastics, you should focus more on the practical differences. This section will dive deeper into how these plastics are different from each other and how that may impact their usefulness in a product. You should note that both of these plastics are useful in tanks, but their differences may mean one is more useful for your specific needs.

Melting Point

The melting points of polyethylene and polypropylene products depend on the specific blend and mixture, but you can look at the general trends to better understand the melting points. Polyethylene is capable of handling higher temperatures than polypropylene and many other plastics. But that does not mean that polypropylene has a low melting point; it just can’t handle the extremes that polyethylene plastic can.

Plastic Durability

Durability comes in many different forms, but in terms of strikes and fatigue, polypropylene is the best choice. Polypropylene can handle hard impacts without breaking and resists stress over time. Products using polyethylene are also durable but do not specialize in high-impact resistance like polypropylene. That is why you will see that most products prioritizing durability will use polypropylene over polyethylene.

Chemical Resistance

When it comes to chemical resistance, which is one of the most important factors of plastic tanks, polypropylene has a specific advantage over polyethylene. Polypropylene can resist a wide array of organic solvents, chemicals, and acids, which is why it is a great choice for a tank. Polyethylene is also resistant to many chemicals, but not as many as polypropylene. In general, if you need corrosion-resistant tanks, you should choose polypropylene.

The Opacity

One of the minor differences between these two plastics is how opaque you can make them for your requirements. While it may not be the most important factor for the purposes of a tank, it is still good information to have so you can choose what you want. Polyethylene can be quite opaque or almost transparent while keeping its other functions. This makes it great for tanks where you want to see the liquids inside, whether for presentation or knowing how much is left in the tank. Polypropylene tanks cannot have the same transparency and will be mostly opaque in most cases.

Cold Temperatures

When it comes to temperatures on both sides of the spectrum, polyethylene is the winner. Polyethylene plastic can handle cold temperatures and still operate and stay intact at much lower temperatures than polypropylene plastics. This means that the plastic will not become brittle at temperatures far lower than what polypropylene can withstand, making polyethylene ideal for cold storage or places with temperature fluctuations.

Electrical Insulator

While it is unlikely that you will need to run electricity through these two plastics, it is good to know that both are great electrical insulators. They both resist electrical currents and will help protect the contents of the tank from electrical charges. However, polyethylene can hold an electrostatic change, which can cause some issues if you are unaware and store the tank somewhere dangerous.

The Weight

When comparing the weight of plastics, you must look at how density and other parts can affect the weight, not just the overall products. It is best to consider raw plastic when choosing a material because of its weight. Between polyethylene and polypropylene, the ethylene polymer is significantly lighter. This is important for anyone making a product out of this plastic, as its lightness will make it a lot easier to move and handle. This is especially important for tanks you want to move after filling.

Production Costs

When it comes to picking out a material for your tanks, the cost of the material will be one of the most important things you consider. You want a tank that can meet all your needs while costing you the least amount of money in the end. Between the two types of plastics to consider here, polypropylene is the less expensive material for plastic items. While you should choose the plastic that is capable of holding what you need it to hold, you should still be aware of the cost difference between the two.

Recycling the Plastic

Another big difference between polyethylene and polypropylene tanks is how to get rid of the tank and the effects of disposing of it. If you are sending it to a recycling plant, polyethylene is a great choice because it is easy to recycle into other products. However, polyethylene is a big consumer of resources and puts out a lot of carbon dioxide. Additionally, the recycling process is not easy, and it is slow to degrade in landfills, lasting decades.

The most important thing to remember when choosing the plastic tank you need is which one can hold your contents for the length of time you need. People require tanks for different reasons, so one tank may work for you but not for another person. It is most important that you find the plastic that best fits your needs.