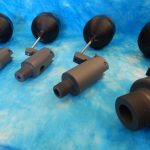

Miller Plastic Products specializes in the production of high-quality precision CNC custom machined plastic parts made to your exact specifications.

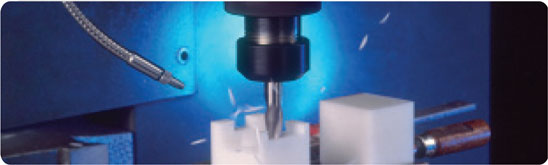

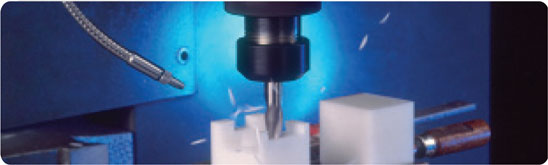

Miller Plastic Products only uses state-of-the-art CNC routing equipment for our precision plastic machining services. We also offer conventional plastic machining services for the production of high-quality plastic components at competitive prices. Our equipment consists of manual Lathes to 5 Axis machining devices and everything in between.

Many of our custom machined plastic parts are annealed for maximum strength and durability. This ensures you receive the quality part your company deserves.

Nothing leaves our facility with sharp or non-machined edges. This is a standard process for us that allows our clients to receive a nice, clean, ready-to-use custom-made plastic part.

We also offer engineering, drafting, welding, annealing, plastic polishing, molded part alterations and more, always for all of your custom plastic fabrication needs.

Contact Us Today for More Information:

Custom Plastic Machining Services

We pride ourselves on having the best CNC machining tools to complete our plastic machining services. Our 5 axis capabilities allow us to machine complex parts with fewer setups saving our clients both time and money.

Our CNC Lathes are Equipped with milling heads, live tooling, and sub spindles that can turn a wide range of parts from custom micro machining up to turning 32 inch diameter stock.

Our Milling capabilities are from micro milling up to 6-foot x 10-foot mill tables. Most of our machines are 5 axis and can machine three-dimensional parts very efficiently.

Plastic Machining Capabilities & Benefits

- Most Materials in Stock

- Many Products Annealed for Maximum Strength

- Post Machining Inspection with 100% Inspection Reports Available

- Custom Parts Made from Samples, Prints, or Sketches

- Precision Plastic Components, Custom-Machined to Your Specifications

- Produce Parts from All Types of Plastics

- Complete CNC & Conventional Machining Facilities

Machining Plastics vs. Molding Plastics

- Plastic machining services do not require an expensive mold to produce parts

- Difficult-to-Mold certain Materials Used

- Plastic Machining will give Closer Tolerances

- Parts can be Altered Cost-Effectively

- Accommodate Parts with Threads & Undercuts at Multiple Angles

Inspection Capabilities:

- Full 3D CMM (Coordinate Measuring Machine)

- Ability to Scan and Completely Reverse-Engineer Even Your Most Complex Parts

- Complete Digitizing Capability With Laser-Scanner

- CMM Can Completely Scan a Part or Gear and Produce a Useful Model

- Ability to Scan and Completely Compare Your Parts to CAD Model