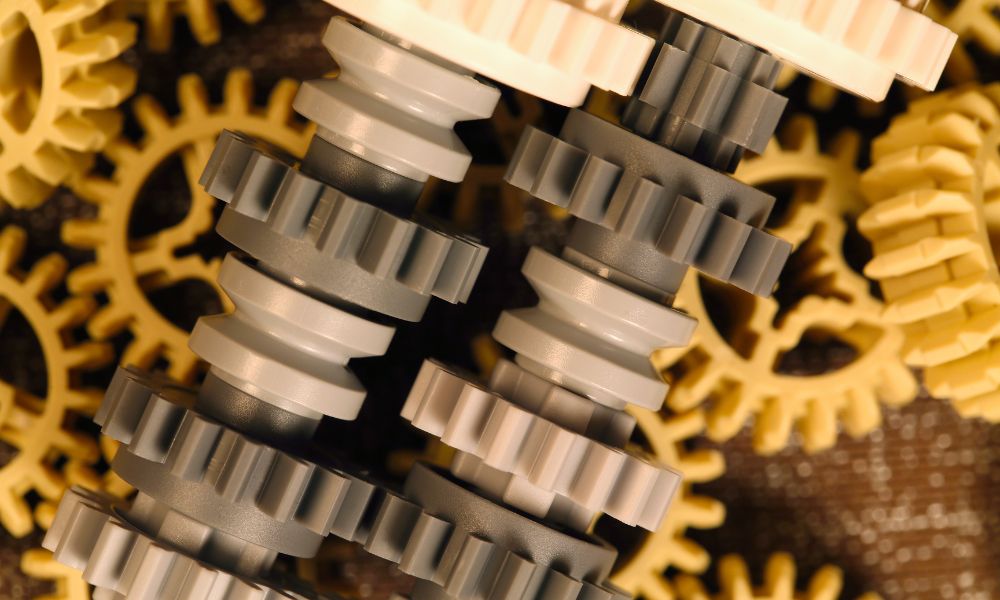

There are countless products and machines that use plastic gears in their designs. Plastic gears are great for manufacturers, as they’re durable options that are both cheap and easy to mold into whatever design you need. However, you still need to regularly inspect your plastic gears. Here’s how.

Manufacturer’s Manual

The first thing you need to do when inspecting your plastic gears is to determine how often you should check them. Regular inspections are important parts of preventative maintenance and should be in your care schedule. The best way to determine the timing of your inspections is with the manufacturer’s manual, which should have guidelines for you. You can get these manuals even if you order from a custom gear manufacturer.

Cleaning Gears

One of the best advantages of running an inspection is that you can use the time to perform basic maintenance tasks for your plastic gears. You should always clean your gears when you check them for damage and issues. A good wipe-down with a soft material will help you keep them clean and running.

Gear Lubrication

Gears constantly push against each other, which causes lots of damage over time as the hard materials grind together. Lubrication helps prevent damage from rubbing surfaces by promoting movement and reducing wear on the parts. However, you need to replace the lubricant often to keep the plastic gears from wearing down.

Signs of Problems

While you should often inspect your plastic gears for issues and damage, you must know what to look for. Cracks or warps in the plastic gears should indicate problems or regular wear from using the device. You’ll need to replace these parts with new gears before they fully break and damage the rest of the device.

Plastic gears are vital for the operation of many important machines and devices around the country. So learning these rules for inspection should help you maintain a healthy system. Just keep in mind how often you should run inspections, and you’ll have a system that works for you.