Custom plastic parts can only add up to a strong, solid whole if they’re secured together well. And just as with metals, welding is often the answer. There are several different techniques for welding plastics that can increase the possibilities for the final result’s shape, size, and complexity.

The Welding Process

The process of welding plastics is about creating a molecular bond between two compatible thermoplastics. And yes, it works better than Super Glue. The steps include:

- Preparation. Each surface has to be examined for flaws, or the bond won’t be as effective. Cleaning the plastic can help make it smooth.

- Pressure. Technicians use vises and other ways to apply consistent pressure to the plastics being welded.

- Heating. The plastic is softened by heat in a variety of ways, or made pliable with a solvent, so the edges can join together.

- Cooling. You can continue to apply pressure during this step to help the part retain its shape. Otherwise, you’re risking shrinkage.

Each material has its own temperature for entering the thermoplastic state, usually ranging between 220 and 380-degrees Fahrenheit. When pressed together, the material’s molecules create a new bond. The techniques mostly differ when it comes to heating or using a solvent. But the method you choose is secondary to the material you choose. The plastic has to be carefully evaluated to ensure that it’s pliable enough for weldability.

Weldable Plastics

A thermoset material can’t be welded because it can’t be re-melted. Thermoplastics are what you’ll be welding, because they can re-melted and re-shaped more than once. Among the thermoplastics you can count on to form a strong, permanent bond:

- Polypropylene (PP), which is both extremely elastic and resistant to chemicals.

- Polyvinylchloride (PVC), which is valued for being lightweight, rigid, and resistant to fire.

- Chlorinated polyvinyl chloride (CPVC), which can withstand high temperatures.

- High-density polyethylene (HDPE), which has a broad strength-to-density ratio.

Typical Applications

Welding is used in plastic product manufacturing for industries that want to avoid any complications from corroding metal components. It’s often recommended for medical devices, semiconductors, chemical and gas transport, and the life sciences. You’ll find it in these industries:

- Aeronautics: holding tanks and interior panels

- Agricultural: fencing and tanks

- Automotive: bumpers and battery cases

- Marine: water holding tanks and fish holding wells

- Plumbing: pipes and drains

Different Ways To Weld

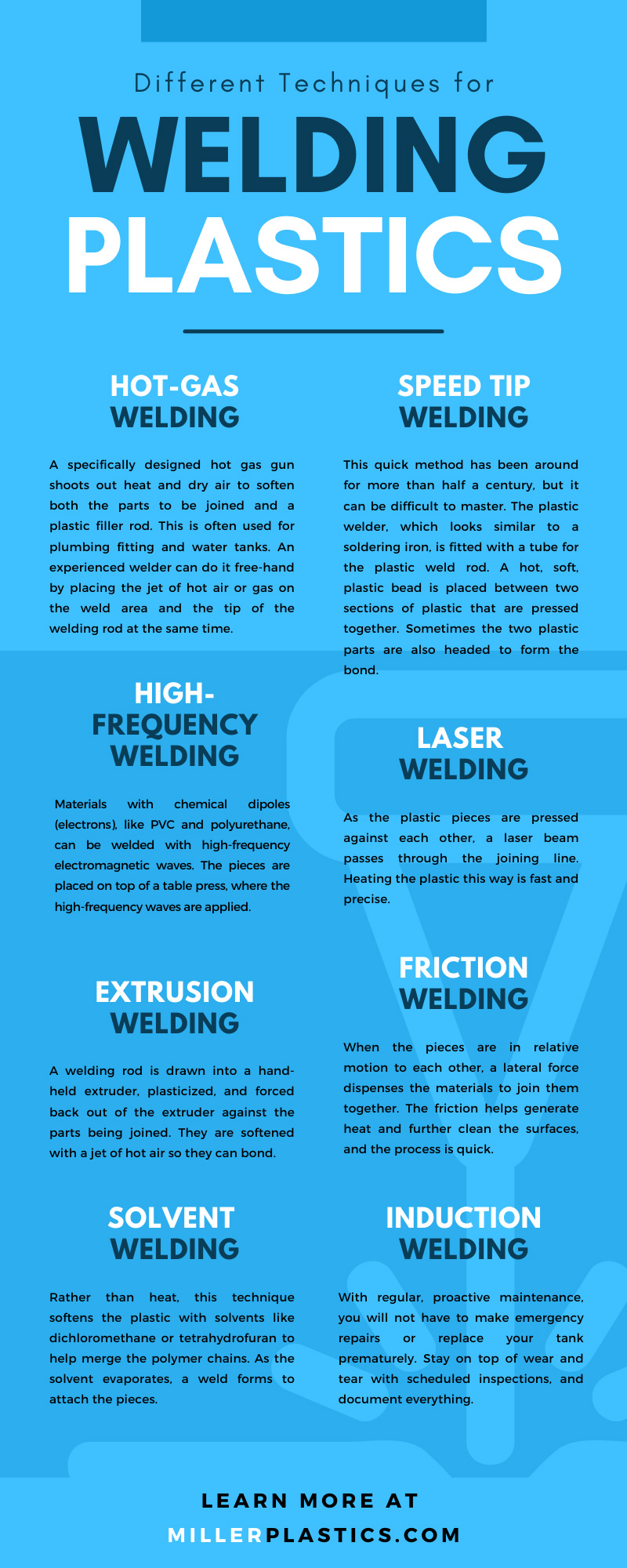

Hot-Gas Welding

A specifically designed hot gas gun shoots out heat and dry air to soften both the parts to be joined and a plastic filler rod. This is often used for plumbing fitting and water tanks. An experienced welder can do it free-hand by placing the jet of hot air or gas on the weld area and the tip of the welding rod at the same time. As the rod becomes more pliable, it is pushed into the joint and fuses to the parts.

Speed Tip Welding

This quick method has been around for more than half a century, but it can be difficult to master. The plastic welder, which looks similar to a soldering iron, is fitted with a tube for the plastic weld rod. A hot, soft, plastic bead is placed between two sections of plastic that are pressed together. Sometimes the two plastic parts are also headed to form the bond.

High-Frequency Welding

Materials with chemical dipoles (electrons), like PVC and polyurethane, can be welded with high-frequency electromagnetic waves. The pieces are placed on top of a table press, where the high-frequency waves are applied.

Laser Welding

As the plastic pieces are pressed against each other, a laser beam passes through the joining line. Heating the plastic this way is fast and precise.

Extrusion Welding

A welding rod is drawn into a hand-held extruder, plasticized, and forced back out of the extruder against the parts being joined. They are softened with a jet of hot air so they can bond. It’s an ideal method for materials over 6 millimeters thick because you can apply bigger welds in a single pass.

Friction Welding

When the pieces are in relative motion to each other, a lateral force dispenses the materials to join them together. The friction helps generate heat and further clean the surfaces, and the process is quick.

Solvent Welding

Rather than heat, this technique softens the plastic with solvents like dichloromethane or tetrahydrofuran to help merge the polymer chains. As the solvent evaporates, a weld forms to attach the pieces.

Hot-Plate Welding

A hot metal plate is coated with polytetrafluoroethylene to prevent sticking, then used to apply heat over the plastic surfaces. The pieces are held together until they cool. It’s often used for larger parts, or those that have a complex weld joint geometry.

Induction Welding

A conductive metal piece is placed between the two plastic pieces, and then heated with a high-frequency generator. After softening, the pieces bond together.

Commonly Asked Questions

Can you use a soldering iron?

Plastic welding has its own equipment. A soldering iron isn’t as successful as the proper tools for creating a permanent bond.

Can you weld different plastics together?

It depends on the variables involved, but in general, it’s not recommended as the strongest way to attach them.

What technique is best?

It depends on the raw materials that need bonding. In some cases, the plastics react better to a chemical solvent bond. With others, a heat bond will have a better result.

How do you decide on a technique?

It ultimately comes down to what the components will be used for. Some plastics are longer-lasting than others, and they respond to the methods in different ways. Each project is evaluated for combined factors that point to the best solution.

It helps to be familiar with the different techniques for welding plastics, but a respected company like Miller Plastics can give you the best options for your project. Whatever method you select, it will give your components a strong bond to withstand the toughest conditions for a long life of service. Let us know how you envision your project, and we’ll help get you there. Contact us through our website, or visit us anytime in Burgettstown, Penn.