Although you may think of 3D printing as a single technique, there are actually several kinds of technologies that make additive manufacturing more versatile than you can imagine. It takes different printers to create them all, so you’ll need to find a manufacturer with the specific equipment you need. Then, you can consult with them about what different method is best for 3D printing your custom parts.

All forms of 3D printing create objects by adding materials layer by layer. But there are lots of variables, and as we develop more sophisticated techniques, you can expect things to become more complicated. For now, though, you can choose from one of these methods.

Stereolithography (SLA)

This is a form of plastic 3D printing that starts with liquid resin. You place the resin in a vat, and underneath, an ultraviolet laser creates a pattern on it to begin the design. That layer cures and solidifies, and the machine then forms another layer. As the object takes shape, a lifting platform drags it upward.

Digital Light Processing (DLP)

In DLP, tiny mirrors control conventional light sources to cure the surfaces of the 3D-printed layers. This technique uses a liquid crystal display panel as a photomask to unleash the light, which allows it to harden the resin more efficiently.

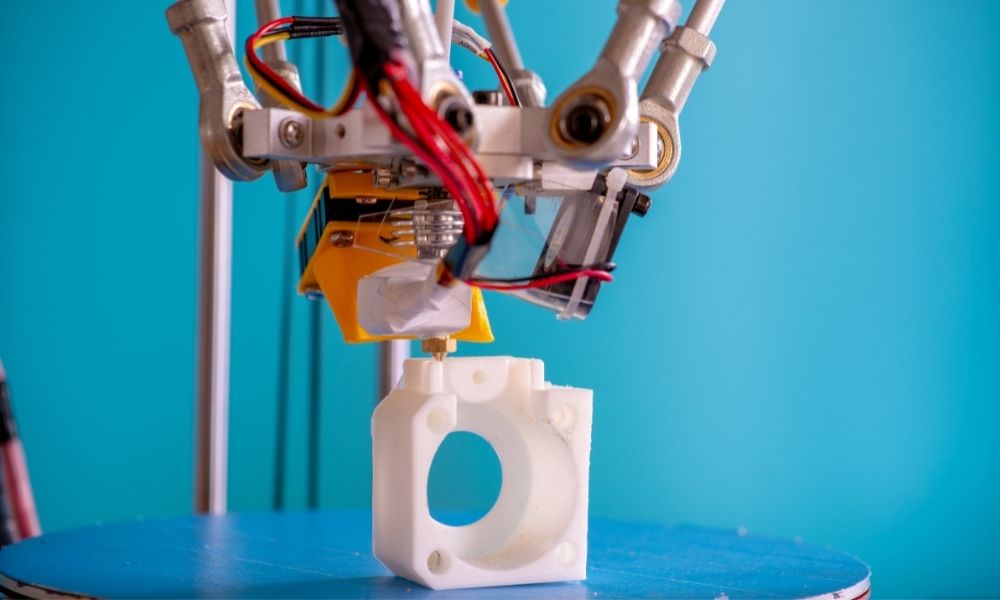

Fused Deposition Modeling (FDM)

With production-grade thermoplastics, FDM printers heat a filament until it reaches its melting point to create layers. You can customize FDM for more complicated designs as well. If a complex structure needs extra support, the 3D printer can extrude another material to do the job. When it’s no longer needed, the machine removes that material.

Laminated Object Manufacturing (LOM)

You might choose this option for rapid prototyping. It’s fast, inexpensive, and can even produce large parts. Using metal laminates, plastic, or paper, LOM fuses layers of coated material with adhesive. After heating and applying pressure, the machine cuts the object into shape with a laser cutter or a knife.

Selective Laser Sintering (SLS)

If you’re using powdered material, you might go for SLS. As with SLA, you place the material in a vat. From there, a roller applies pressure to each layer. Then, the printer laser-sinters the object you’re creating into the desired pattern.

Selective Laser Melting (SLM)

Where SLS sinters powdered material, SLM instead melts the material completely. Otherwise, it’s the same process.

Electronic Beam Melting (EBM)

This method is similar to SLM. But in place of a high-powered laser, an electron beam melts the metal powder. The machine heats the printing bed and maintains vacuum conditions in it while forming the object.

With the equipment and expertise needed to carry out all these different methods for 3D printing your custom parts, Miller Plastics can match a technique to your project. Custom designs require custom 3D printing services with the latest technology. Contact us to learn more about our state-of-the-art facilities in Burgettstown, PA, near Pittsburgh.