Polypropylene (PP) is a versatile plastic that has been around since the 1950s. Despite its widespread use, several misconceptions persist about it. In this blog post, we aim to debunk common myths about polypropylene, offering clarity for manufacturers and sustainability enthusiasts alike.

Myth 1: Polypropylene Products Are Low Quality

There’s a misconception that products made from polypropylene are of low quality. In reality, PP products are known for their durability, flexibility, and resistance to chemicals and wear. These qualities make them suitable for high-stress applications requiring corrosion-resistant plastic.

From reusable containers to automotive components, polypropylene products often outperform those made from other materials. Their ability to withstand harsh conditions without degrading ensures long-term reliability and functionality.

Myth 2: Polypropylene Is Unsafe for Food Packaging

Another common misconception is that polypropylene is unsafe for food packaging. This myth likely stems from concerns about chemicals leaching into food. However, polypropylene is approved for food contact by regulatory bodies like the FDA and EFSA.

PP is highly resistant to chemicals and does not react with food substances. It’s widely used in food containers, microwaveable dishes, and even baby bottles due to its safety profile. Its stability ensures it does not release harmful substances when in contact with food.

Myth 3: Polypropylene Is Inferior to Other Plastics

Some people believe that polypropylene is inferior to other plastics like polyethylene or PVC. This is far from the truth. Polypropylene boasts several superior qualities, such as resistance to fatigue, flexibility, and a high melting point. These properties make it suitable for a wide range of applications.

Polypropylene’s resistance to wear and tear makes it ideal for automotive parts, while its thermal resistance makes it perfect for microwave-safe containers. Its versatility extends to textiles, where it’s used in everything from carpets to activewear.

Myth 4: Polypropylene Is Expensive

Many manufacturers shy away from using polypropylene, thinking it is more expensive than other materials. However, the cost-effectiveness of PP becomes evident when you consider its durability and performance.

Polypropylene’s long lifespan and resistance to chemical and physical wear mean that products made from it often last longer, reducing replacement costs. Additionally, as recycling technologies improve, the cost of producing recycled PP decreases, making it an economically viable option.

Myth 5: Polypropylene Is Difficult To Work With

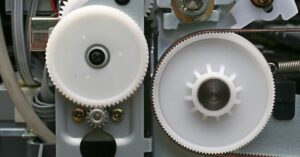

Some people believe that polypropylene is challenging to mold and shape. While it does require specific processing conditions, advances in manufacturing technology have made it easier to work with. Techniques like injection molding and extrusion have streamlined the production process.

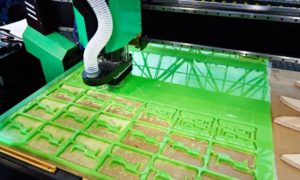

Modern machinery and tools have simplified the handling of PP, making it accessible even for small-scale manufacturers. Additionally, innovations like 3D printing are expanding the possibilities for using polypropylene in complex designs and prototypes.

Leverage This Key Material for Improved Productivity

Polypropylene is a versatile and valuable material that plays a crucial role in modern manufacturing. No matter what industry you’re in, understanding the materials you’re working with can help you make informed decisions and improve productivity. Debunking these common myths about polypropylene is key to appreciating its benefits and potential.