Our custom plastic fabrication service capabilities are second-to-none. Through innovative and skillful uses of turning, milling, bending, rolling, welding, and annealing, we manufacture durable, long-lasting precision parts.

As custom plastic fabricators, our specialization in plastics and polymers gives us detailed knowledge of plastic materials and their characteristics.

This high level of expertise makes it possible for Miller Plastic Products to complete custom plastic parts fabrications and components of the highest quality.

We stock most materials and have the ability to do everything from prototyping to production runs.

Miller Plastics is a custom plastic fabrication company that was built on the quality of their product. All our custom plastic fabrications are made to laboratory standards, and our welds are second to none, being very smooth and easily cleaned. Nothing leaves our shop with a saw cut edge or a sharp edge. Every piece is individually cut out on high-tech CNC dual head routers. We also perform custom acrylic fabrication and other fabrication services. To see detailed characteristics of materials we use, please view our material spec charts.

To learn how well various plastics can withstand certain chemicals, take a few minutes and review our Chemical Resistance Properties Chart.

Read more about our custom plastic fabrication services below.

Plastic Machining Capabilities & Benefits

- Plating and Storage Tanks

- Wet Benches

- Pipe Systems

- Ductwork

- Filtration Systems

- Chemical Feeders

- Ventilation Systems

- Exhaust Hoods

- Custom Battery Boxes

- Lithium Iron Phosphate Battery Boxes

- LiFePO4 Battery Boxes

Plastic Welding

As part of our plastic fabrication services, Miller Plastics are experts at plastic welding, which involves joining various components and structures together, generally with the aid of heat and proprietary mixes of specific gases.

We have the ability to weld a variety of non-metallic materials including Kynar, PVC, CPVC, Polypropylene, Polyethylene, and much more.

Custom Plastic Fabrication Processes Include

- Precision, Close-Tolerance Cutting of All Materials

- CNC Butt Welding

- Pipe Bending

- Precision CNC Machining and Routing

- Strip Heat Bending

- Annealing of Most Products for Maximum Strength

- Extrusion Gun Welding

- Highly Efficient Part Programming

- Welding

- Speed Tip Welding and Hand Welding

- Cementing

- Plus More!

Some of the Materials We Work With Include:

Custom Plastic Fabrication Services

- Computer-Aided Design Assistance (CAD/CAM)

- Custom CAD Drawings

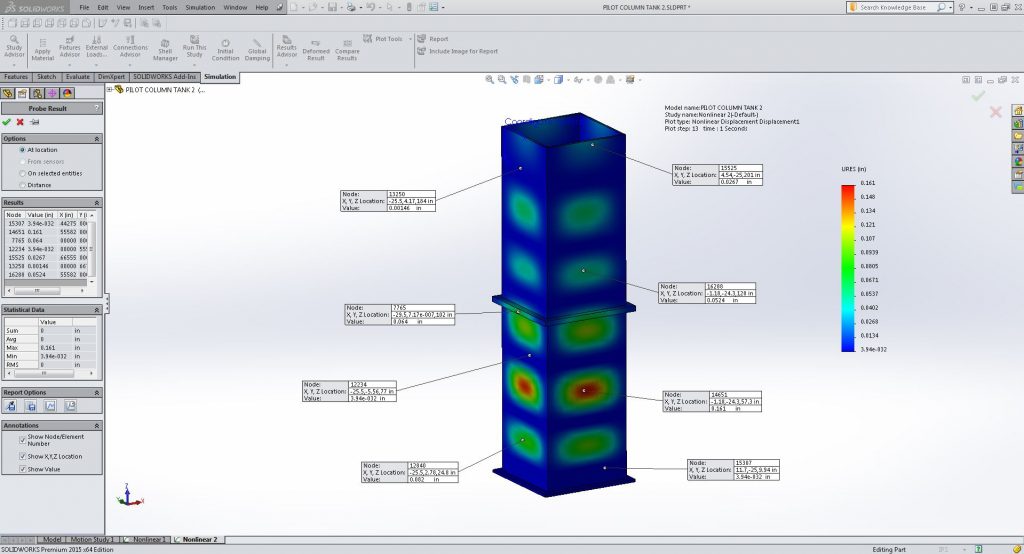

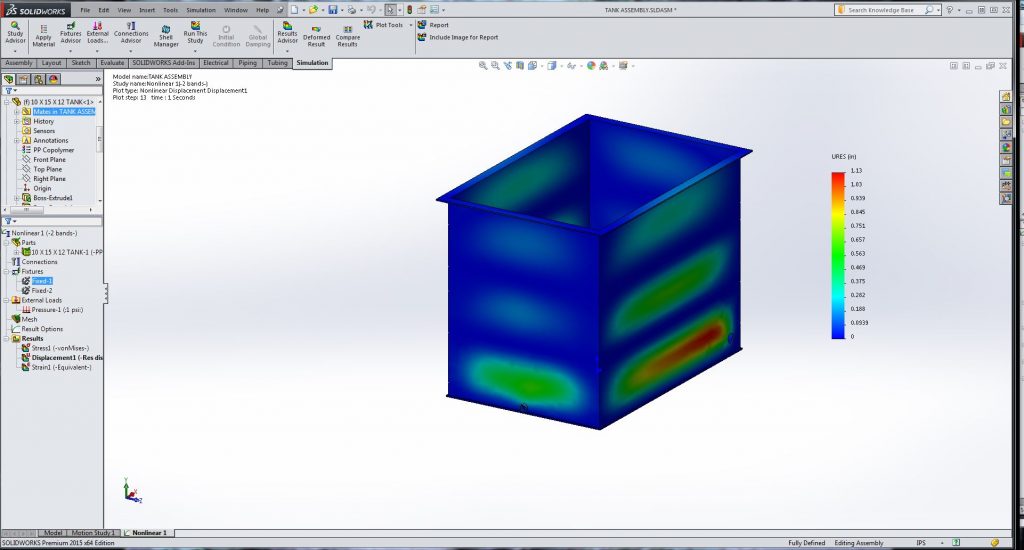

- FEA Structural Analysis

- Assembly

- Solvent & Adhesive Bonding

- Pipe Bending

- Pipe Systems

- Quality Inspections of All Parts

- Cementing

- Active JIT Programs

- Annealing

- Highly Efficient Part Programming

GET A CUSTOM PLASTIC TANK QUOTE

Our experience can help you choose the right material for your particular custom plastic tank. We’re just a phone call or click away.

We offer free design assistance and can provide 2D or 3D drawings using AutoCAD and SOLIDWORKS

Our tanks are engineered using FEA (Finite Element Analysis) to maximize performance and allow for minimal bowing of the fabrication.