With all the different processes, materials, and innovations developing in the plastics industry, we’ll forgive you for not being able to spell “polytetrafluoroethylene.” But if you’ll be designing your own components, there are some words you should understand. A glossary of terms used in plastic manufacturing will cover some of the basics.

Additive Manufacturing

Additive Manufacturing is another term for 3D printing. A CAD model or scan is reproduced as a three-dimensional object, layer by layer. It dramatically cuts down on material waste.

Annealing

A process of heating and cooling to permit stress relaxation without distortion of shape.

Aspect Ratio

The length-to-diameter ratio of materials or fibers.

CAD

An acronym for Computer Aided Design.

Chemical Resistance

The degree to which a plastic will resist degrading because of contact with various chemicals. It can vary with chemical concentration and temperature.

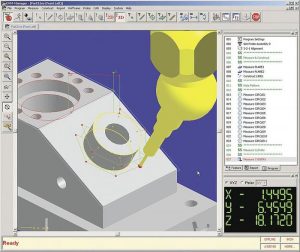

CNC Machining

CNC is an acronym for Computer Numerical Control. CNC machining is a subtractive process with computerized controls and machine tools that remove layers of materials from a stock piece to produce a custom-designed part.

Crazing

This refers to small, hair-like cracks beneath the surface of a plastic part. It often indicates imminent fracture.

Creep

Creep is the tendency of a solid material to move slowly or deform permanently under stress. It’s sometimes called “cold flow.”

Dimensional Stability

The ability of a part to retain its size and proportion over time.

Extrusion

Extrusion is processing plastic by forcing softened plastic through an opening of the desired shape of the cross-section of a finished product.

Finish

This is a type of surface treatment applied to the part. It can range from a smooth to a contoured pattern, improving the appearance and/or the feel.

Plasticizer

A plasticizer is a chemical agent or solvent added to plastics to make them softer and malleable.

Polymer

A polymer is a substance with a molecular structure that consists of a large number of similar units bonded together.

Polymerization

This is a chemical change that forms a new compound with a molecular weight that’s a multiple of the original substance.

Subtractive Manufacturing

This is the process of cutting pieces off of a solid block of material.

Thermoset

Thermosets are materials that can be melted only once during the original processing. They can’t be reprocessed after the original part has been manufactured.

Thermoplastic

A thermoplastic is any material that can be re-melted and recast repeatedly.

Turning

This is when a tool is held against the stock to remove material and create a cylindrical part.

Of course, this is only a very brief glossary of terms used in plastic manufacturing. At Miller Plastics, we’re used to explaining things clearly to our customers. If you need custom machined plastic parts, we’ll be happy to work with you on the best processes and materials for your design. Contact us for more information—although our spelling’s probably not any better than yours.