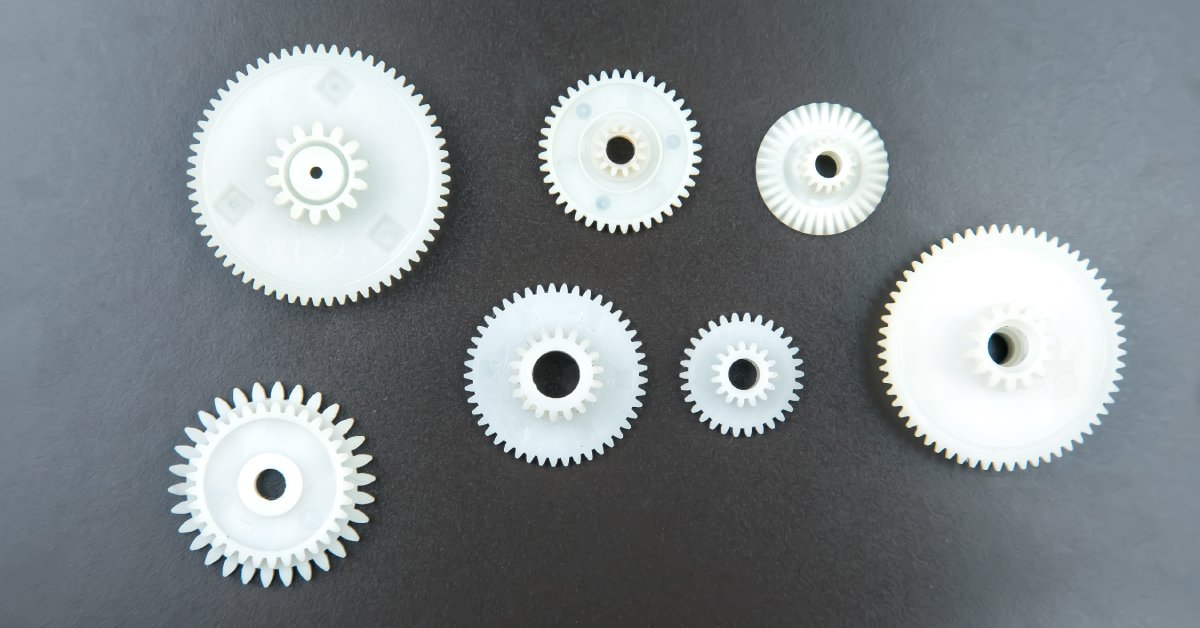

Plastic gears are an essential part of modern machinery. Understanding how they’re made is key to choosing the right type for your application. Let’s take a closer look at injection-molded and machined plastic gears so you can decide which is the best for your needs.

How Are Injection-Molded Gears Made?

Injection molding creates plastic gears by forcing melted material into a mold. This process allows for high-volume production with consistent results. It’s perfect for making gears in larger quantities at lower costs.

Manufacturers design molds to create complex shapes with exact specifications. This method is ideal for lightweight gears requiring less customization. However, there might be some limitations to this approach where precision is crucial. This method works best with specific types of plastic, which makes it less flexible in terms of material choices.

What Differentiates Machined Plastic Gears?

Manufacturers craft machined plastic gears by shaping solid plastic blocks or rods into the desired gear design. It’s a more hands-on process requiring skilled technicians and specialized equipment.

This method produces gears with finer details and tighter tolerances. It is the go-to option when durability and precision are nonnegotiable for critical applications. However, this can lead to higher production costs, especially for small runs.

If you’re looking for custom solutions, a custom gear manufacturer can help meet specific application requirements. Their expertise ensures you get a product designed just for you.

Which Option Suits Cost-Sensitive Projects?

Injection-molded gears often win in cost-sensitive projects. Their production process creates many gears in a single batch, significantly reducing the cost per unit. For high-volume production, the savings can be substantial.

On the other hand, machined gears, while costlier, offer unmatched flexibility. The ability to tweak designs without creating a new mold can result in cost benefits for one-off or low-quantity runs.

How Do Material Choices Differ?

Injection molding limits material options to what can be efficiently melted and molded, like polypropylene or nylon. These materials are lightweight, cost-effective, and suitable for general applications.

Machined gears are not confined to thermoplastics that melt. The process allows the use of stronger and more versatile plastics like PEEK or PTFE. This makes them the better choice for environments where heat, chemicals, or wear resistance come into play.

Are Precision and Accuracy Affected?

Precision is an area where the differences between the two methods become apparent. While injection-molded gears are consistent, their tolerances don’t match the exacting standards of machined gears.

Machining ensures unparalleled detail and dimensional accuracy. This makes it the go-to choice for industries like aerospace and robotics, where every fraction of a millimeter counts.

When comparing injection-molded and machined plastic gears, both methods have their place. While injection molding offers cost-effective production in high volumes, machining allows for greater flexibility, durability, and precision. The choice between the two methods ultimately depends on factors such as budget, volume, and application requirements.

For projects requiring machine-crafted plastic components with high precision and quality, contact Miller Plastic Products. We use state-of-the-art equipment and processes to deliver exceptional results tailored to your needs.