Polypropylene, a versatile and popular plastic, plays a significant role in the food industry. It helpsto preserve, protect, and promote quality from farms to tables worldwide. Exploring this material’s impact on the food sector can provide valuable insights into modern practices and innovations. Let’s uncover the various applications of polypropylene, its benefits, its challenges, and how it shapes the food industry today.

Understanding Polypropylene’s Versatility

Polypropylene is a thermoplastic polymer widely used in various industries due to its adaptability and versatility. It is lightweight and durable, which makes it an ideal choice for numerous applications. In the food industry, polypropylene serves important roles in packaging, storage, and transportation.

This material’s ability to withstand different temperatures without breaking down maintains food safety and quality throughout the supply chain. Businesses often turn to polypropylene for its cost-effectiveness and environmental benefits, making it a popular choice in today’s eco-conscious world.

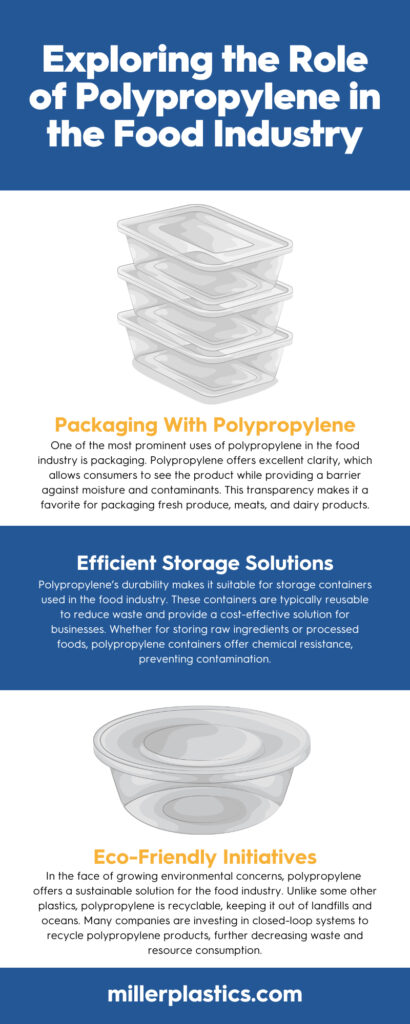

Packaging With Polypropylene

One of the most prominent uses of polypropylene in the food industry is packaging. Polypropylene offers excellent clarity, which allows consumers to see the product while providing a barrier against moisture and contaminants. This transparency makes it a favorite for packaging fresh produce, meats, and dairy products.

The material’s high melting point means it can be safely used in microwaveable containers and other heat-sensitive applications. By choosing polypropylene packaging, companies enhance the shelf life and safety of their products, leading to greater consumer satisfaction.

Efficient Storage Solutions

Polypropylene’s durability makes it suitable for storage containers used in the food industry. These containers are typically reusable to reduce waste and provide a cost-effective solution for businesses. Whether for storing raw ingredients or processed foods, polypropylene containers offer chemical resistance, preventing contamination.

Their stackability and lightweight nature make them easy to transport and store, streamlining operations for food manufacturers and distributors alike. Using polypropylene storage solutions, companies can maintain product quality and consistency across supply chains.

Transportation and Logistics

Polypropylene plays a necessary role in the food industry’s transportation and logistics. Its robust nature makes it ideal for creating pallets and crates used to transport goods safely and efficiently.

Polypropylene products minimize damage during transit and protect valuable food resources from farm to table. Additionally, polypropylene’s lightweight characteristics reduce shipping costs and carbon emissions, aligning with sustainability goals.

Enhancing Food Safety

Food safety remains a top priority for the food industry, and polypropylene contributes to this goal. The material’s resistance to chemicals and bacteria makes it an excellent choice for food contact applications, such as cutting boards and food processing equipment.

Polypropylene does not leach harmful substances into food, which keeps products safe for consumption. Furthermore, its ease of cleaning and sterilization enhances food safety practices and minimizes the risk of contamination.

Eco-Friendly Initiatives

In the face of growing environmental concerns, polypropylene offers a sustainable solution for the food industry. Unlike some other plastics, polypropylene is recyclable, keeping it out of landfills and oceans. Many companies are investing in closed-loop systems to recycle polypropylene products, further decreasing waste and resource consumption.

These efforts contribute to a more sustainable food industry, which can appeal to eco-conscious consumers. With polypropylene’s eco-friendly credentials, businesses can demonstrate their commitment to environmental stewardship while meeting regulatory requirements.

Cost-Effective Manufacturing

The affordability of polypropylene makes it an attractive option for food manufacturers seeking cost-effective solutions. Its low production costs enable companies to create high-quality products without breaking the bank.

The material’s adaptability also allows for customization, meeting diverse packaging and storage needs across the industry. By choosing polypropylene, businesses can achieve economies of scale, reducing expenses and passing savings on to consumers. This cost-effectiveness ensures that the food industry can maintain competitive pricing while delivering superior products.

Innovation in Food Preservation

Polypropylene’s role in food preservation is essential for maintaining quality and freshness. Vacuum sealing with polypropylene films helps extend the shelf life of perishable goods, reducing food waste. This innovation benefits both consumers and businesses by ensuring that products remain fresh for longer periods.

Additionally, you can tailor polypropylene films to meet specific preservation needs, such as moisture control or oxygen barrier properties. By leveraging polypropylene’s capabilities, the food industry can continue to innovate in preservation techniques, driving profitability and sustainability.

Addressing Health Concerns

Polypropylene’s non-toxic nature addresses health concerns associated with other materials used in the food industry. It does not release harmful chemicals, such as BPA, into food products, making it a safe choice for consumers.

This safety assurance maintains consumer trust and loyalty in an increasingly health-conscious market. By using polypropylene, companies can demonstrate their dedication to protecting public health while providing high-quality products.

The Value of Custom Solutions

Polypropylene’s versatility allows for custom solutions tailored to specific food industry needs. From intricate packaging designs to specialized storage containers, manufacturers can adapt polypropylene to fit unique requirements. This flexibility benefits businesses by providing products that meet their specifications, enhancing efficiency and performance.

For those who need a polypropylene tank, Miller Plastic Products offers an array of customized options. By investing in custom solutions, companies can optimize their operations and achieve greater success.

Exploring Future Applications

The future of polypropylene in the food industry holds exciting possibilities for innovation and growth. Emerging technologies, such as smart packaging, offer new opportunities for enhancing product quality and consumer experience. Polypropylene’s adaptability and versatility make it an ideal material for smart packaging. Smart packaging refers to incorporating technology into packaging materials to enhance product quality, safety, and consumer experience.

Polypropylene, being a thermoplastic polymer, can easily incorporate various technologies such as RFID tags, sensors, and indicators without compromising its properties. This adaptability enables businesses to stay ahead of trends by continuously evolving their packaging solutions to meet changing consumer demands.

For example, with the rise of e-commerce and online shopping, consumers now expect more convenience and transparency in their product packaging. By using polypropylene in smart packaging solutions, companies can offer features like real-time tracking and temperature monitoring that address these expectations.

Polypropylene continues to revolutionize the food industry through its diverse applications and benefits. The future of the food industry lies in the continued integration of this versatile material. Companies looking to enhance their operations can explore polypropylene’s potential through custom solutions offered by Miller Plastic Products. We make all of our products meet laboratory standards to give you the best quality options.