Non-ferrous metals have revolutionized manufacturing and engineering. Ferrous metals contain iron, while non-ferrous metals are free from iron, giving them unique properties that make them indispensable in various industries. Understanding non-ferrous metals is essential for manufacturers, engineers, and metalworkers. Read this in-depth overview of non-ferrous metals to help you succeed in your industry.

The Importance of Non-Ferrous Metals in Industry

Non-ferrous metals play a vital role in modern industries. They offer unique properties—corrosion resistance, light weight, high conductivity, and non-magnetic behavior—that make them desirable for various applications.

Manufacturing

Understanding the importance of non-ferrous metals translates into better material selection and improved product performance. Non-ferrous metals, like aluminum, copper, and titanium, are useful in the production of automobiles, aircraft, and machinery parts due to their high strength-to-weight ratios.

Engineering

In the field of engineering, non-ferrous metals have opened up new possibilities for design and innovation. For example, using aluminum instead of steel in construction results in lighter structures that require less energy to transport and erect. This not only reduces costs but also has a positive impact on the environment.

Other High-Demand Sectors

Non-ferrous metals are foundational in high-demand sectors like aerospace, construction, and renewable energy. Their ability to withstand harsh conditions while maintaining their properties supports their usefulness.

Common Types of Non-Ferrous Metals

Understanding the various types of non-ferrous metals is crucial for manufacturing. Non-ferrous metals possess distinct properties that manufacturers can take advantage of for various applications.

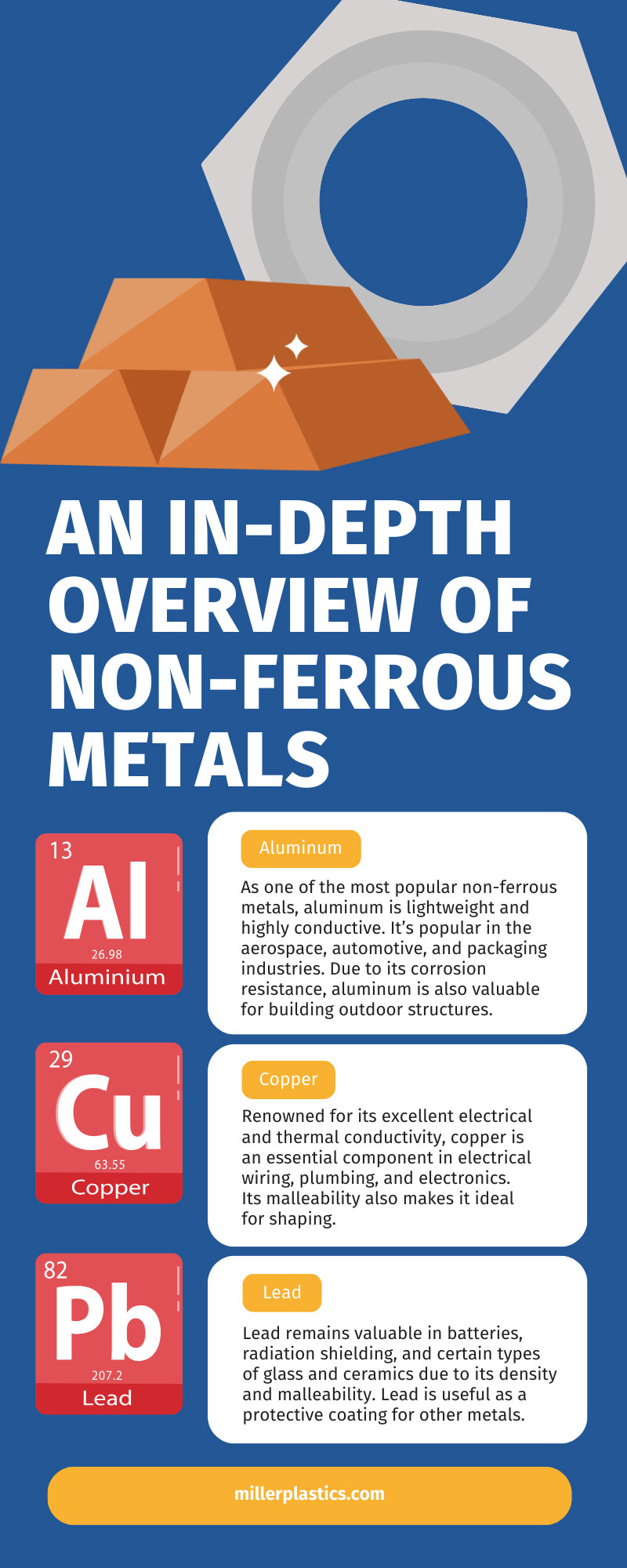

Aluminum

As one of the most popular non-ferrous metals, aluminum is lightweight and highly conductive. It’s popular in the aerospace, automotive, and packaging industries. Due to its corrosion resistance, aluminum is also valuable for building outdoor structures.

Copper

Renowned for its excellent electrical and thermal conductivity, copper is an essential component in electrical wiring, plumbing, and electronics. Its malleability also makes it ideal for shaping.

Lead

Lead remains valuable in batteries, radiation shielding, and certain types of glass and ceramics due to its density and malleability. Lead is useful as a protective coating for other metals.

Zinc

Zinc offers excellent corrosion resistance and is common in galvanizing steel, die-casting alloys, and making brass. Manufacturers prefer zinc to produce batteries, fertilizers, and paints.

Titanium

Titanium is crucial in aerospace, medical implants, and sporting goods due to its strength-to-weight ratio, corrosion resistance, and biocompatibility. It also benefits the production of high-performance vehicles.

Benefits of Non-Ferrous Metals Over Ferrous Metals

Comprehending the advantages of non-ferrous metals over ferrous metals facilitates informed decision-making in material selection. It also ensures manufacturers choose the best metal for any given application.

Corrosion Resistance

Non-ferrous metals such as aluminum and copper resist corrosion better than ferrous metals. They are ideal for outdoor applications and marine environments where rust would weak metals containing iron.

Lightweight

Non-ferrous metals such as aluminum and titanium are much lighter than ferrous metals. This property is especially beneficial in the aerospace and automotive industries, where reducing weight is crucial for efficiency and performance.

High Conductivity

Metals like copper and aluminum possess excellent electrical and thermal conductivity. This quality makes them the preferred choices for electrical wiring, heat exchangers, and other applications requiring efficient energy transfer.

Challenges and Precautions When Working With Non-Ferrous Metals

Non-ferrous metals have specific processing requirements, which can complicate machining and forming operations.

Machining Difficulties

Non-ferrous metals can be softer or harder than ferrous metals, posing challenges in machining. Using appropriate tooling techniques is essential to avoid material deformation or tool wear. To mitigate these issues, machinists often use specialized cutting fluids, high-speed steel (HSS) tools, or even diamond-tipped tools.

Health Hazards

Lead can pose significant health risks if not handled properly. Adequate protective measures and adherence to safety standards are critical when working with toxic, non-ferrous metals. This includes wearing protective gear, avoiding ingestion of fumes or particles, and safely disposing of waste.

Cost Considerations

Non-ferrous metals can indeed be more expensive than their ferrous counterparts due to several factors, including scarcity, the process of extraction, and the properties they offer. When material performance, longevity, and attributes like corrosion resistance and light weight matter most, the long-term benefits and cost savings justify the high initial cost.

Sustainable Practices in Non-Ferrous Metal Manufacturing and Use

Traditional resource extraction can lead to soil degradation, deforestation, and water pollution. On the other hand, sustainable practices aim to minimize these effects through resource-efficient methods and pollution control.

Recycling

Recycling non-ferrous metals is one of the most sustainable practices. Metals like aluminum and copper can be recycled indefinitely without losing their properties, contributing to resource conservation and reducing environmental impact.

Energy Efficiency

Implementing energy-efficient processes in the extraction and refining of non-ferrous metals reduces the impact of such practices. Innovations in energy use, such as electric arc furnaces, play a role in sustainable practices.

Responsible Sourcing

Responsibly sourcing non-ferrous metals is crucial for preserving the environment. Ethical mining practices and adherence to environmental regulations can minimize the negative impact on ecosystems and local communities.

By adopting these sustainable practices, we can continue to benefit from non-ferrous metals while promoting environmental stewardship and social responsibility.

Future Trends in Non-Ferrous Metals

The future of non-ferrous metals is bright. Continuous advancements in technology and materials science are pushing the boundaries of what’s possible.

Advanced Alloys

The development of advanced, non-ferrous metal alloys promises enhanced properties for various applications. These alloys can offer superior strength, corrosion resistance, and conductivity, paving the way for innovative solutions.

Additive Manufacturing

Additive manufacturing, or 3D printing, is revolutionizing the use of non-ferrous metals. This technology enables the customization of complex components with minimal waste, driving efficiency and creativity.

Green Technologies

Non-ferrous metals support the advancement of green technologies, from electric vehicles to renewable energy systems, and the transition to a more sustainable and eco-friendly industrial landscape. Staying abreast of these trends helps manufacturers, engineers, and metalworkers harness the full potential of non-ferrous metals.

An Indispensable Part of Modern Industry

Non-ferrous metals are indispensable in modern industry, and this in-depth overview can help you leverage their unique properties and advantages. By understanding these metals, professionals can maximize their benefits.

Custom plastic products are the perfect way to start exploring the potential of non-ferrous metals and stay ahead in your field. Integrating these insights into your operations can help you refine your material selection and applications.