Plastic machining is the process of cutting, shaping, and finishing plastic materials to produce custom-made parts for specific applications. It’s crucial in various industries, including the aerospace, medical, automotive, and electronic sectors. As the demand for customized plastic parts has grown, precision has become a key factor in delivering high-quality components that meet industry standards and offer reliability.

The Importance of Precision in Plastic Machining

To understand why precision is so important in plastic machining, you should learn more about its specific benefits. Here’s a look at some of the main ones.

Fixing Errors and Improving Quality

Precision is essential in the production and design of plastic parts, as it ensures consistency, accuracy, and repeatability. By utilizing high-precision techniques and technologies, manufacturers can quickly identify and fix errors during the machining process. High-precision manufacturing helps improve production line quality and minimize the risk of defects in the final products.

Consistency Across Components and Industries

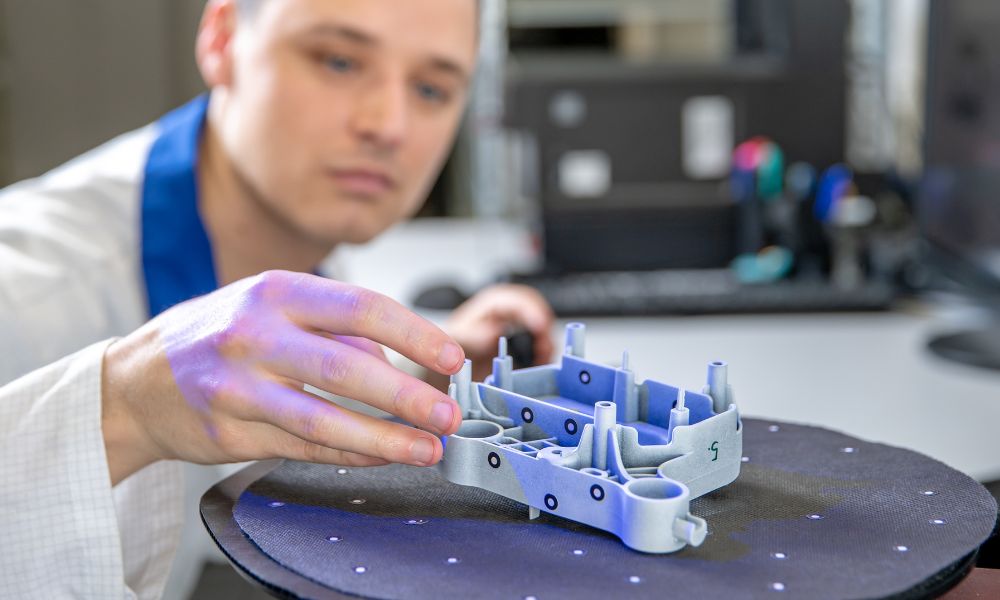

One of the significant advantages of precision in plastic machining is ensuring consistency across all components. By meeting industry standards and consistent tolerances, manufacturers can create high-quality, custom-made plastic parts that function seamlessly in various applications. For example, precision manufacturing has aided the aerospace industry in producing lightweight, highly durable components that meet rigorous safety standards.

Cost and Time Savings

Precision in plastic machining can lead to significant cost and time savings for both businesses and clients. By streamlining the production process and reducing errors, manufacturers can cut operational expenses, save time during assembly, and minimize labor costs. Consequently, clients can receive a better return on their investment and quicker access to essential components.

Impact of Precision on Businesses

Companies that invest in precision machining can benefit from a competitive advantage by providing their customers with high-quality components that deliver better performance and longevity. Enhanced precision in manufacturing not only helps businesses gain customer trust but also leads to increased customer satisfaction, which directly translates to repeat business.

Essential Steps for Achieving Precision in Plastic Machining

Implementing high precision in manufacturing is easy if you know what steps you need to follow. Here’s a look at some of the basics to improve precision in your processes.

- Selecting the right machining process: Various machining methods, such as milling, turning, and drilling, provide different levels of precision. Choosing the most appropriate technique for a given application is crucial to achieving the desired accuracy.

- Implementing quality-control measures: Integrating efficient quality-control measures throughout the machining process ensures that the parts are within the specified tolerances.

- Utilizing advanced technologies: Employing state-of-the-art tools and equipment, such as computer numerical control (CNC) machines, guarantees improved precision in manufacturing.

- Investing in a skilled workforce: Manufacturers must invest in skilled technicians capable of managing complex tools and machinery to maintain high levels of accuracy during the machining process.

There are many factors that make precision in plastic machining essential for producing high-quality plastic parts that meet industry standards and suit various applications. It improves product quality consistency and reduces costs for manufacturers and clients. By focusing on essential steps and implementing modern technologies, businesses can achieve desired precision levels and secure a competitive edge in the market.