In any machinery or equipment, selecting the appropriate gear size is a crucial part of ensuring optimal performance and longevity. The size is even more important for plastic gears, which are vital across various industries due to their lighter weight and lower production costs. Delve into the world of plastic gears and read through this comprehensive guide to choosing the right size for your specific application. We aim to equip you with the knowledge that’ll save you from the consequences of poor gear selection and instead maximize the efficiency and durability of your equipment.

Understanding Plastic Gears

As the name suggests, plastic gears use various plastics and can replace metal gears in specific applications. Their advantages include reduced weight, enhanced lubrication, decreased noise, and cost-effectiveness.

There are different types of plastic gears, such as spur gears, helical gears, and worm gears, each with applications. Understanding these gear types and their strengths and limitations will aid you in selecting the appropriate gear size for your application.

Importance of Gear Size Selection

Selecting the correct gear size is crucial to ensuring your machinery’s smooth and efficient functioning. Poor gear size choices can lead to lost power, increased wear and tear, and higher repair costs. In some cases, it may even result in catastrophic failure of your equipment.

To illustrate the impact of gear size on performance, consider a gear system in an automotive gearbox where the gears don’t match in size. In this situation, you may experience poor acceleration, increased fuel consumption, and eventual transmission failure.

Factors To Consider While Choosing Gear Size

Several factors come into play when determining the appropriate gear size for your application.

Torque

First and foremost, torque is pivotal in choosing the gear size. Torque is the force that’s responsible for rotation. It’s crucial to select a gear size capable of handling the torque your specific application requires. If your gear is too small, it might not be robust enough to manage the necessary torque and could experience quick wear and tear or breakage.

Speed

Speed is another pivotal factor that affects the gear size selection. The rotational speed of your gears can significantly impact your decision. For instance, if you have high-speed applications, you often require smaller gears to enhance efficiency. Conversely, you might need larger gears for low-speed applications to ensure better torque transmission.

Efficiency

Efficiency is one of the primary goals while selecting the appropriate gear size. Choosing the right gear size can prevent power loss, generate less heat, and extend the gear system’s lifespan. An apt gear size selection can substantially amplify the efficiency of your equipment.

Durability

Durability is another significant factor linked with the right gear size. Choosing the correct size helps in evenly distributing forces across the gear teeth, which, in turn, minimizes wear and tear. Proper size helps extend your gears’ lifespans and contributes to your equipment’s overall durability.

Material

The material of the gear is a significant factor to consider in gear size selection. Different materials offer varying levels of strength, hardness, and resilience, which can affect the overall performance and durability of the gear. For instance, plastic materials such as nylon have excellent wear resistance, while others offer superior dimensional stability. Therefore, the choice of material should align with the needs of your specific application. Note that the material you choose can impact the gear sizes available to you.

Cost

Cost is another crucial aspect of gear selection. While the initial gear cost might be a deciding factor, it’s also important to consider the long-term costs associated with maintenance, replacement, and potential downtime. Therefore, when selecting the gear size, one should balance cost-effectiveness and operational efficiency.

Availability

The availability of a gear in a particular size can also influence your decision. It’s important to consider whether the required gear size is readily available or requires custom manufacturing. While custom gears offer the advantage of suiting specific requirements, they might require more time and money to manufacture.

Custom Gear Options

Finally, you should explore custom gear machining options when the available gear sizes do not meet the specific requirements of your application. With custom machining, you can order gears that meet your project’s exact needs. However, this option might incur additional costs and require a longer lead time.

Consequences of Poor Gear Selection

Improper gear size selection can lead to various issues, including noisy operation, vibrations, excessive wear, and even failure of the entire gear system. One real-world example is the failure of a gear system in a large industrial machine due to incorrect gear size selection. This breakdown results in costly downtime for the company and a significant loss of production.

The mismatch between the gear size and the machine’s operational needs causes excessive stress and accelerated wear, ultimately leading to the gear system’s failure. A company experiencing this issue would have to halt production for several days to replace the damaged gears and restore the machine’s functionality, incurring financial losses and delayed delivery schedules. This example serves as a demonstration of the importance of proper gear size selection in industrial machinery.

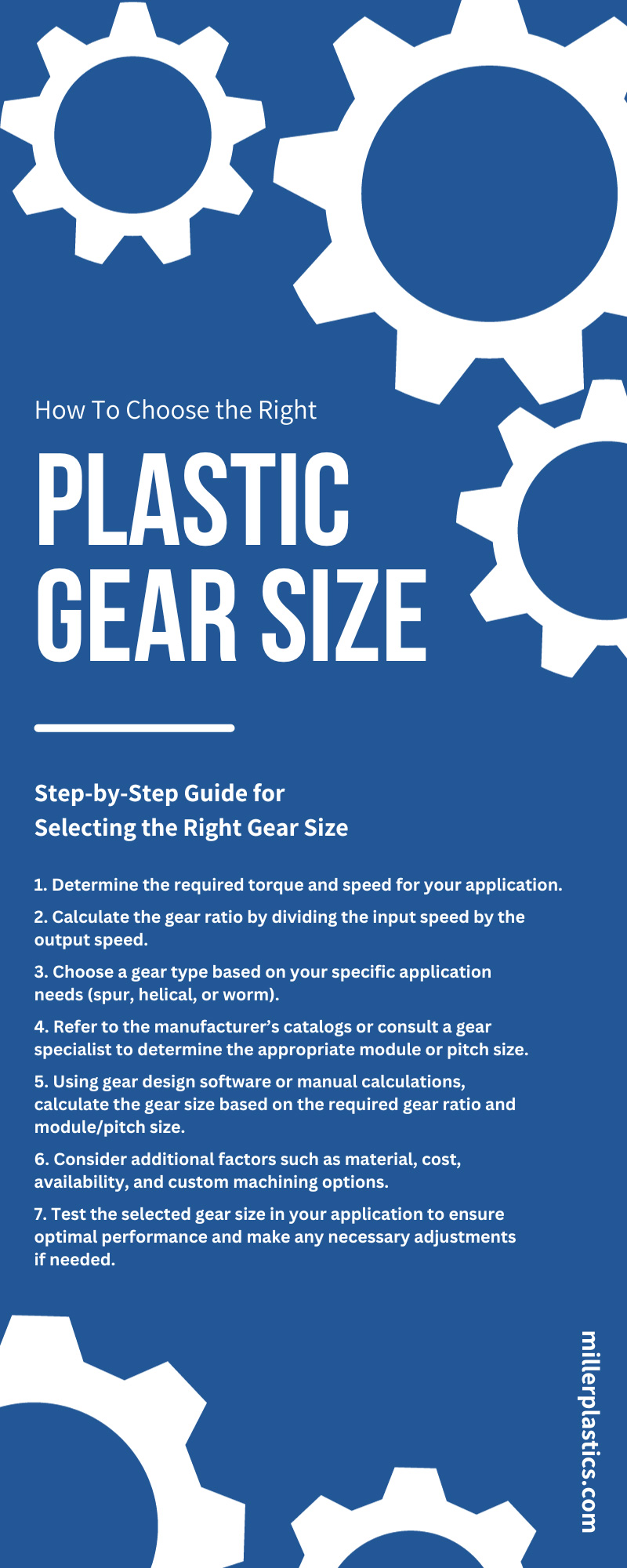

Step-by-Step Guide for Selecting the Right Gear Size

To select the correct gear size for your application, follow a few straightforward steps.

- Determine the required torque and speed for your application.

- Calculate the gear ratio by dividing the input speed by the output speed.

- Choose a gear type based on your specific application needs (spur, helical, or worm).

- Refer to the manufacturer’s catalogs or consult a gear specialist to determine the appropriate module or pitch size.

- Using gear design software or manual calculations, calculate the gear size based on the required gear ratio and module/pitch size.

- Consider additional factors such as material, cost, availability, and custom machining options.

- Test the selected gear size in your application to ensure optimal performance and make any necessary adjustments if needed.

Learning how to choose the right plastic gear size is crucial to achieving maximum efficiency and durability in your equipment. By understanding the factors that influence gear size selection and following a systematic approach, you can avoid the consequences of poor gear sizing and protect your machinery. Remember to consult with experts or refer to manufacturer’s catalogs for specific application requirements, and always test the selected gear size before implementation.