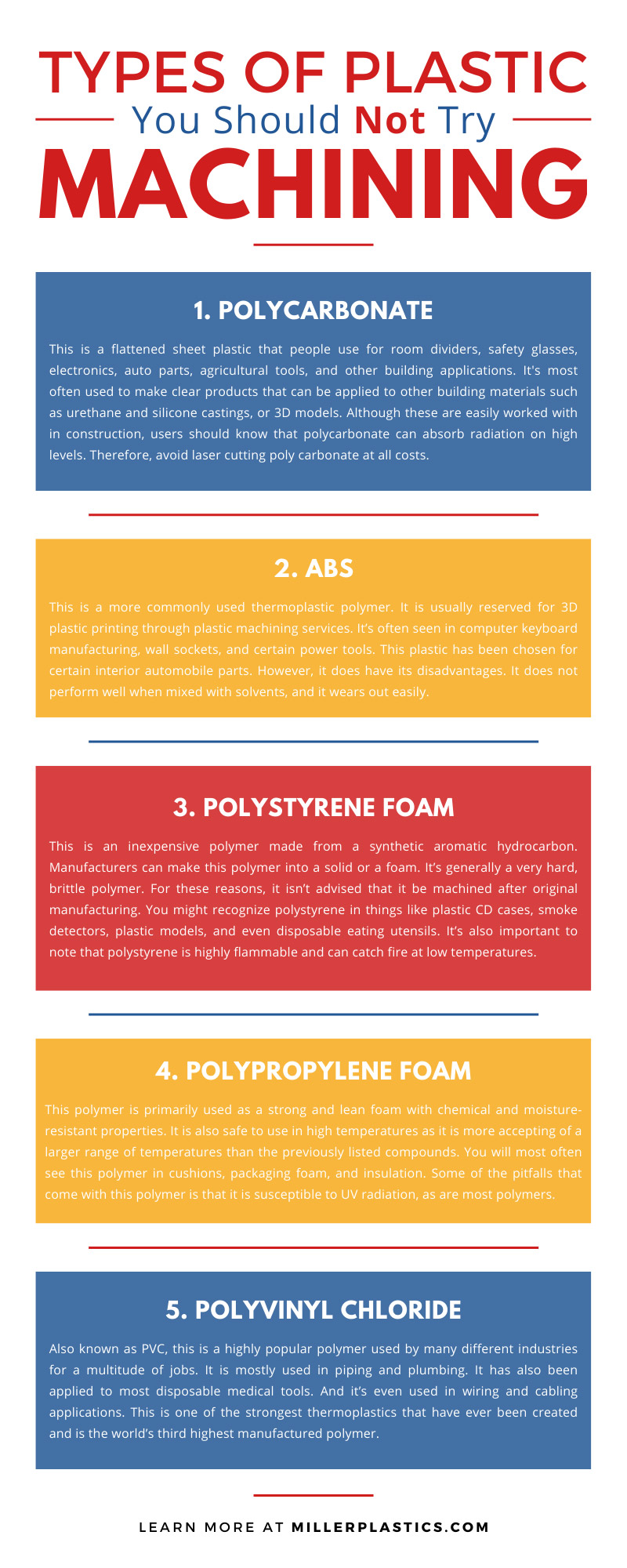

There are a multitude of plastics in the world that all serve different purposes. Some can only perform one job and others have more flexibility to do many. Some plastics have recently been engineered to be recycled and renewed, while others cannot be renewed. Those that aren’t as renewable are usually cannot be machined for the same or similar reasons. This is a list compiled of the seven types of plastic you should not try machining due to specific guidelines that these plastics have.

1. Polycarbonate

This is a flattened sheet plastic that people use for room dividers, safety glasses, electronics, auto parts, agricultural tools, and other building applications. It’s most popular use is it makes clear products that can be applied to other building materials such as urethane and silicone castings, or 3D models. Although these are easily worked with in construction, users should know that polycarbonate can absorb radiation on high levels. Therefore, avoid laser cutting poly carbonate at all costs. It also does not like being cut, thus you will have a hard time attempting to cut this material, and it can easily catch fire under certain conditions.

2. ABS

This is a more commonly used thermoplastic polymer. It is usually reserved for 3D plastic printing through plastic machining services. It’s often seen in computer keyboard manufacturing, wall sockets, and certain power tools. This plastic has been chosen for certain interior automobile parts. However, it does have its disadvantages. It does not perform well when mixed with solvents, and it wears out easily. It has low resistance to UV rays unless it has something defending it. The temperature range that it can stand without melting or deforming is 70 degrees Celsius to 160 degrees Fahrenheit. Needless to say, it smokes easily, and these are just some of the reasons why it’s the plastic should not be machined or reformed in any way after its fabrication.

3. Polystyrene Foam

This is an inexpensive polymer made from a synthetic aromatic hydrocarbon. Manufacturers can make this polymer into a solid or a foam. It’s generally a very hard, brittle polymer. For these reasons, it isn’t advised that it be machined after original manufacturing. You might recognize polystyrene in things like plastic CD cases, smoke detectors, plastic models, and even disposable eating utensils. It’s also important to note that polystyrene is highly flammable and can catch fire at low temperatures.

4. Polypropylene Foam

This polymer is primarily used as a strong and lean foam with chemical and moisture-resistant properties. It is also safe to use in high temperatures as it is more accepting of a larger range of temperatures than the previously listed compounds. You will most often see this polymer in cushions, packaging foam, and insulation. Some of the pitfalls that come with this polymer is that is susceptible to UV radiation, as are most polymers. It has very little defense against chlorinated solvents or any kind of aromatics. So, these are things to look out for if you use this product. It doesn’t bond well with other things, so machining or attempting to reconstruct it in different forms isn’t advisable. Although it may have a wider range in temperature to other foam polymers, it should also be noted that it has a high flammability.

5. Polyvinyl Chloride

Also known as PVC, this is a highly popular polymer used by many different industries for a multitude of jobs. It is mostly used in piping and plumbing. It has also been applied to most disposable medical tools. And it’s even used in wiring and cabling applications. This is one of the strongest thermoplastics that have ever been created and is the world’s third highest manufactured polymer. As popular as this plastic is, you wouldn’t believe just how toxic some of the additives are that it contains. Phthalates, lead, cadmium and organotins are just a few substances that it contains which could be harmful if consumed. These plastics, like all plastics, have the tendency to emit chemicals under certain conditions as they age. This gives many levels of reason as to why you should not consider machining this product. The potential of environmental and personal harm that you could be exposing yourself to is extremely high.

6. Polyurethane

This plastic material can be made into many different forms. It doesn’t hold temperature well and has a low capacity for heat. This polymer also weathers very poorly, so you should protect it against the elements. Most solvents will degrade or destroy the compound if they come in contact with it. There are toxic isocyanates contained within the polymer, making it toxic to the environment under certain conditions. And, of course, like most other plastics it is highly flammable.

7. Epoxy Resin

This is already a highly manufactured polymer as it must go through levels of curing to transform what is originally a rough plastic material into a synthetic resin. These resins are used in adhesive applications and surface layering to provide protective coats over things like hard surfaces and flooring. While epoxy is mostly chemical resistant and anti-corrosive, they take a long time to cure and aren’t easily machined once cured as they are so hard that they can become brittle if machined. They are also hard to handle, even once in their hardened state. They can also pose a threat to the environment as they do not biodegrade.

This has been a definitive list of the seven types of plastic you should not attempt to machine or reform for any reason. Hopefully you got some useful information out of this read, but just remember that it’s not a good idea to attempt to recreate or reconstruct these materials for any reason.

If you have any further questions or concerns about this topic, then you can refer to Miller Plastics for all of your polymer needs. We are in the business of creating seamless customer experiences. We will be happy to oblige and help with any of your needs moving forward. Don’t hesitate to reach out for any question. We can and will provide useful information.