Plastic gears are a prominent part of various devices and products, from military devices to toys to production machines. These gears are extremely useful for producing quality goods, but they can break down just like other parts. Here’s what you need to know about plastic gears in your devices and how you can tell when it’s time to replace the gears.

The Purpose of Plastic Gears

You should first know the main purpose of plastic gears and why so many products use them in their design. This section will go over these concepts to help you understand why many manufacturers use plastic for these gears.

The Same as Other Gears

Plastic gears serve the same purpose as other gears, whether they’re metal or wood. By using gears, you can create complex systems to help control the speed or force behind a mechanism. The plastic gears serve the same function, but the material differences can have a big impact.

Cheaper Options

The main reason why so many designs use plastic gears instead of metal ones is that they’re cheaper to produce. Mass production of products is expensive, so anything that reduces the cost of each unit can increase profits immensely.

Durable Material

While plastic is a cheaper alternative to many other materials available, it is still a durable option. Depending on the exact plastic you choose, you can count on the plastic surviving as long as a metal design. Fortunately, you don’t have to lose access to high-quality parts when choosing plastic over metal for your gears.

High Accuracy

Plastic is easy to mold and can retain complex shapes easily, making it perfect for pieces that need high accuracy. You can create plastic parts easily using simple production equipment, even if you need a detailed design. This highly customizable feature of plastic is part of why it’s so popular for gears.

Damage to Plastic Gears

While plastic is a fantastic material that is durable and precise, it still suffers from damage over time. You’ll want to understand the limitations of plastic gears and how they can break to figure out how to best utilize and care for the plastic parts. Once you notice issues, you can contact a plastic gear manufacturer to replace whatever part you need.

Wear and Tear

Any moving part will eventually wear down as it rubs against other things, and plastic gears are no different. While these parts can last a long time, constant use will eventually wear them down and lead to issues. You should replace any parts like this when you notice visible wear.

Broken and Missing Teeth

A common problem for plastic gears is the breakdown of their teeth. Wear will eventually lead to missing teeth on the gear, which can greatly impact how your device operates. You should replace any plastic gears with missing or broken teeth as soon as you notice them.

Warping in Materials

Sometimes the gear will warp as it strains against the other parts of your devices. Warping in your gears can impact productivity and lead to a total halt of operations. You should regularly check for any warping for all the parts of equipment to find what you need to replace.

Running Inspections

When it comes to caring for your plastic gears and any equipment that uses them, you should run frequent inspections to catch any issues. The frequency depends on the importance and delicacy of the device, but you should check each gear at least once a month. This step allows you to catch issues and prevent more damage caused by using bad parts for too long.

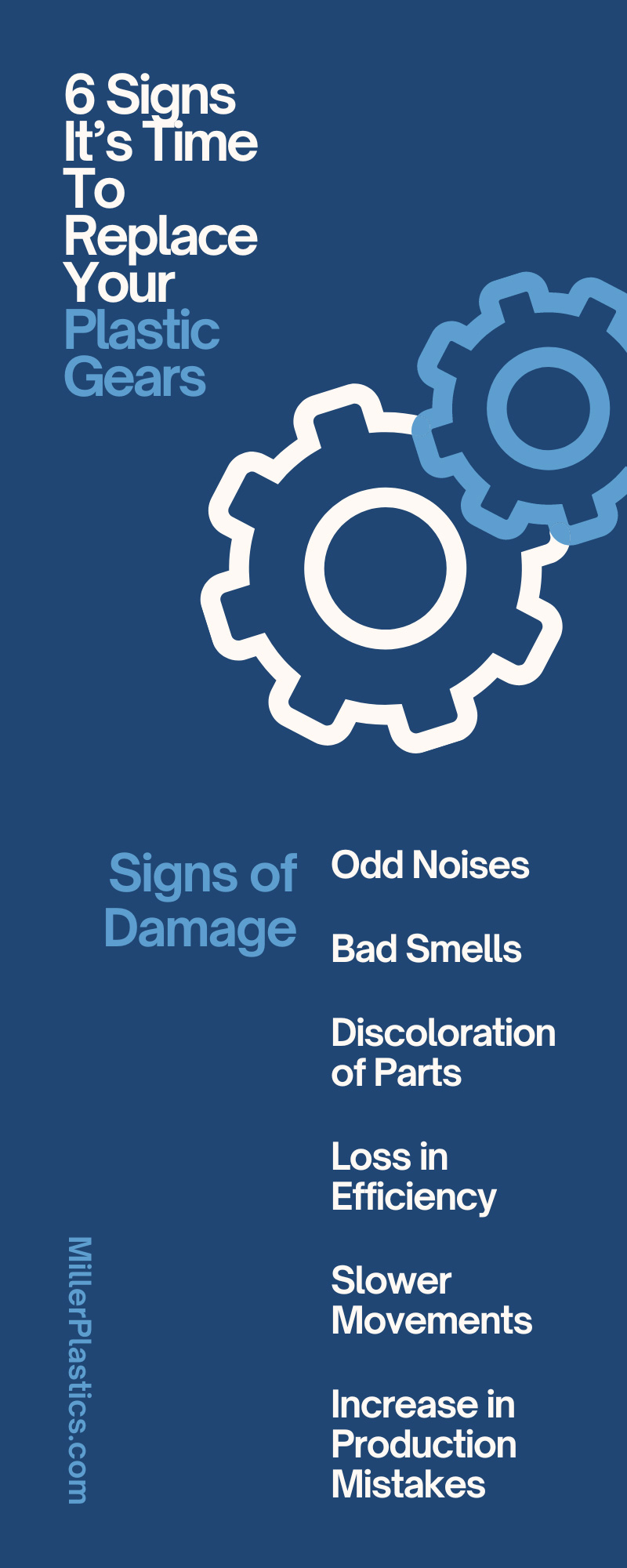

Signs of Damage

Learning what you should keep your eye out for regarding your plastic gears is a big part of identifying the problem. If you can learn these signs now, you can prevent bigger problems down the line by taking immediate action.

Odd Noises

If you ever use the device and notice odd sounds, these noises may indicate that your gears are in bad shape. Common sounds to listen for include a rattling or grinding sound as the gears rub against each other. If you notice these sounds, you should stop your device and check for damage in your parts.

Bad Smells

While bad smells emanating from your equipment is unusual, they can indicate broken gears. A common bad odor is the smell of something burning, as the extra friction from the gears can create a smell. In this situation, you should immediately stop using the item until you can repair it.

Discoloration of Parts

You should check your entire device for any discoloration, as this sign can indicate several issues. Discoloration can indicate that your gears have come from contact with corrosive or abrasive materials, which can damage the plastic. Additionally, warping can cause discoloration, even if you don’t visibly see the change in shape.

Loss in Efficiency

You should track the production of any device that uses plastic gears. Note that a sudden or gradual downturn in efficiency can indicate gear issues. This subtle change can be difficult to track in some items, but you should do your best to look for any decreases in productivity or efficiency over time.

Slower Movements

Any device that uses gears likely moves, and broken or warped gears can lead to slower movements for the device as a whole. If you notice the parts of your equipment move slower than they should or now move in quick, jerky movements, these problems can be signs of gear damage.

Increase in Production Mistakes

Gears use interlocking teeth, and a broken tooth can lead to slipping gears that cause all sorts of issues. Check your plastic gears if you notice more product mistakes stemming from inconsistency in your equipment. Looking for this sign is one of the best methods to determine if your plastic gears need replacement.

Plastic gears are extremely prevalent in equipment and products, so knowing this information can benefit practically every manufacturer. The knowledge of how to identify broken gears can benefit your business, whether you’re using it to maintain your equipment in a production line or improve the products you create. Look for these signs so that you can prevent further damage to your items and your business.