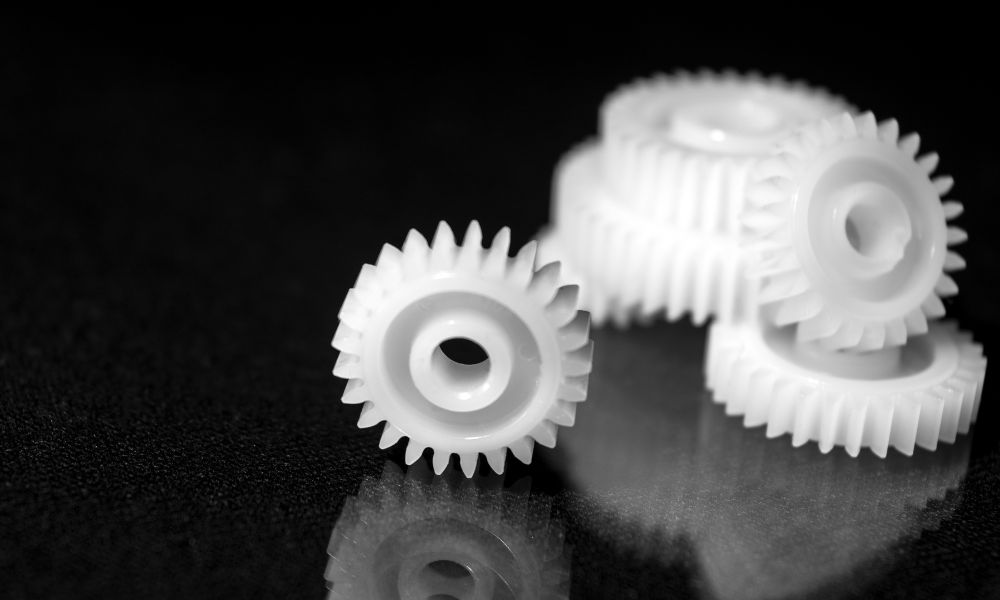

It takes a lot to make good plastic gears, from the design to the material choices to the producer. This article aims to help you make the right decisions for your gears by going over the types of plastic you should use when making gears. All four of these plastics can work, depending on your needs.

Nylon Plastics

Nylon plastic is one of the most common plastics for gears. This material is great for the usual uses of plastic gears. While temperature and humidity can affect the shape, it can self-lubricate, making it a perfect choice for many systems that endure a lot of wear and tear.

Thermoplastic Polyester

This plastic is a great option for gears, as it’s very durable and resistant to heat and corrosion. Thermoplastic polyester is a perfect choice for many devices because it can withstand all sorts of extreme situations. Additionally, it doesn’t suffer from the same issues with water and humidity as nylon.

Acetal Plastics

Acetal plastic is almost the exact opposite of nylon plastic, with great resistance to humidity and temperature. It’s resistant to many chemicals and is quite durable. However, it needs constant lubrication when carrying heavy loads or working for a long time. Acetal plastics are among the most common materials for plastic gears.

Polyamide Plastics

These gears can withstand high torque at low rotation speeds, making them perfect for many different systems and gears. Polyamide plastics can handle corrosive materials and high temperatures, perfect jobs for their light weight and low cost. That’s why you should use this plastic to make your gears.

All of these plastics are great for any project or product you’re working on. It’s important that you understand the benefits and deficits so you can choose the right material. This is how you create the best product possible while keeping your costs low.